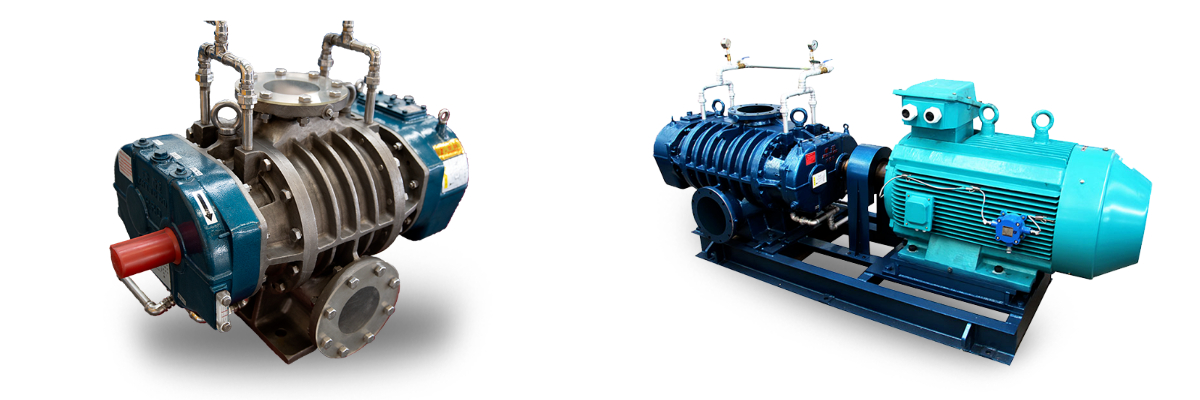

VR Series Steam Roots Compressor

High efficiency and energy saving: The VR series is designed to be highly efficient and to conserve energy.

Wide capacity and pressure range: Offers a broad operating range (evaporation capacity from 30 to 7,400 kg/h and temperature rise of 10–25 °C), accommodating diverse user needs.

Simple, stable structure and easy maintenance: Features various motor-compressor transmission options that ensure reliable operation and simplify upkeep.

Oil-free design with excellent sealing: The design keeps lubricating oil completely separate from steam, and offers customizable shaft seals that guarantee zero leakage.

Shandong Zhangqiu Blower Co., Ltd. is a leading manufacturer of Roots blowers in China, with over 40 years of experience in the design and production of blowers. The company has established joint ventures with Japanese partners and has a subsidiary in the United States, making it the first Chinese blower manufacturer to set up a branch abroad. In July 2011, the company was successfully listed on the Shenzhen Stock Exchange.

The company specializes in the production of Roots blowers and has strong research and development capabilities. It has developed the VR series Roots steam compressors, which are characterized by high efficiency, energy saving, and stable operation. These compressors are widely used in MVR (Mechanical Vapor Recompression) systems for evaporation crystallization and concentration processes.

Main Features of the VR Series Roots Steam Compressors:

1. Wide range of capacity and pressure rise, with evaporation capacities ranging from 30 to 7400 kg/h and temperature rises between 10 to 25°C, allowing users to select the most suitable compressor for their needs.

2. Various transmission modes between the compressor and motor ensure stable operation, with a simple structure that facilitates easy maintenance.

3. Patented impeller profiles provide reliable sealing performance, high efficiency, and energy savings.

4. High machining accuracy ensures reliable operation and a long service life.

5. The casing requires no lubrication, and the design ensures that lubricating oil does not mix with the conveyed steam.

6. Compressor shaft seals can be customized according to user requirements, offering various sealing types with effective performance to ensure zero leakage of conveyed steam.

7. The wetted parts of the compressor can be made from various materials, including carbon steel, SS304, SS316, SS316L, duplex stainless steel, titanium, and special corrosion-resistant coatings, depending on the medium being conveyed.

Ordering Information:

The inlet flow parameters provided for the VR series Roots steam compressors are based on saturated steam at 80°C. If the user's medium differs from this condition, they should contact the company's technical department at zhanggu_fys@163.com.

The company offers various material options for the compressor, including carbon steel, SS304, SS316, SS316L, duplex stainless steel, titanium, and special corrosion-resistant coatings, to meet different user requirements.

When placing an order, users should specify the medium to be conveyed, inlet flow rate, inlet temperature, and required pressure rise or temperature rise. If the standard performance parameters do not meet the user's requirements, the company can customize the Roots steam compressor according to specific needs.

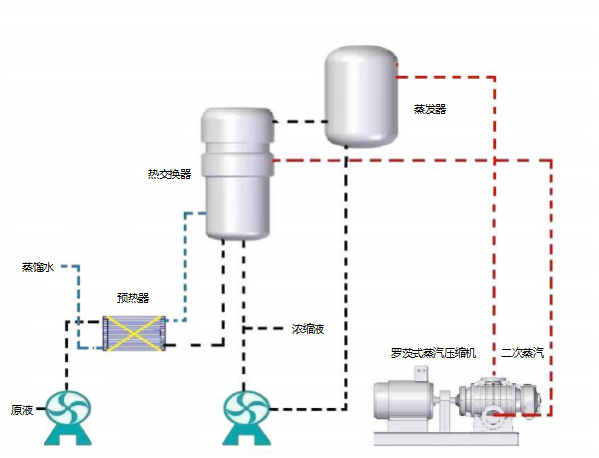

Description of Mechanical Vapor Recompression (MVR)

MVR operates as a closed-loop system. During startup, a small amount of fresh steam is used to initiate boiling of the feed material, producing secondary vapor. Once sufficient vapor is formed, fresh steam supply is cut off. The vapor from the evaporator is separated into steam and liquid via a steam–liquid separator, and the steam is suctioned into the compressor. Upon compression, its pressure and enthalpy increase, and the resulting vapor is reused as the heat source through the heat exchanger. Because this cycle recirculates the vapor, no waste steam is generated—resulting in significant energy savings compared to conventional evaporation systems. By reusing steam internally, MVR achieves both energy efficiency and environmental benefits.In an MVR system, the steam compressor is the core component. The most mature compressor types include centrifugal compressors and Roots-type compressors. While Roots-style steam compressors operate on the same principle as traditional Roots blowers, they handle steam instead of air. For example, when processing water vapor, a Roots steam compressor can achieve a vapor temperature increase of 10–25 °C, making it suitable for scenarios with relatively low evaporation rates but larger boiling temperature elevation.

The following diagram illustrates the MVR process: secondary vapor from the evaporator is compressed—raising its temperature, pressure, and enthalpy—and then returned to the heat exchanger as a heating source. This enables the efficient reuse of latent heat that would otherwise be wasted.

Advanced processing equipment

Application fields

| Seawater Desalination | Landfll Industry | Coal Chemical Industry | Metallurgical Industry |

Petroleum Chemical Industry | Chlor Alkali Chemical Industry | Salt Chemical Industry | Chemical Fber Industry |

| Food Industry | Pharmaceutical Industry | Plating and Materials Surface Coating | Paper Industry |