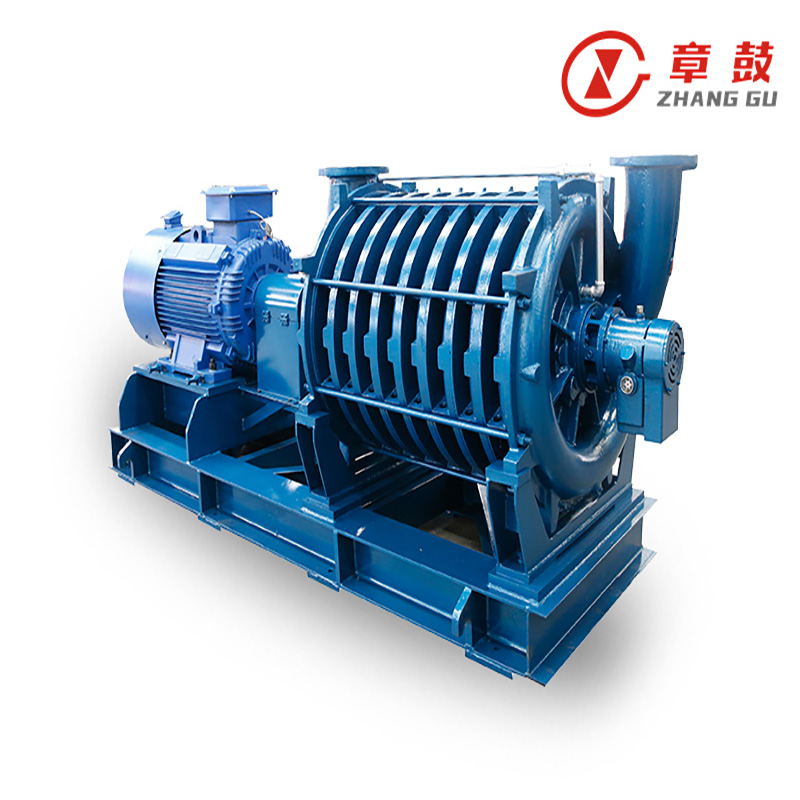

Regenerative Blower

1.The impeller intake diversion ring improves inlet fluidity of impeller.

2.The airfoil return-flow blade can reduces loss ,gets high static pressure.

3.The blower performance was optimized with fluid analysis technology, The poly tropic efficiency is up to 78%> The same blowers meets two rorating speeds of 50Hz and 60Hz, blower range of adjustment is wide and performance better.

Regenerative blower technology is introduced from UsA of most advanced all over the word with highefficiency. Multiple patent technologies are adopted that is obviously better than other Chinese product in lower noise level, lowervibration and higherefficiency.

The blower is consists of stator, rotor, driving device and so on. lt has one suction and two supports. The rotor consistsof multi-stage impellers. Motor and blower are installed independently, or are installed on the same common base accordingto owner’s demand (indicating before order). Motor and blower are direct connected with coupling (The mini-type bloweiconnect with belt). Watching from the tail of motors (For the mini-type blower,it is sh aft protraction), the blowers is clockwiserotation.

Stator:The stator is vertical split type structure, which is consists of the inlet chamber,intermediate casing and discharge scroll case, these parts make up of the gas channels withbolts. The inlet chamber, intermediate casing, and discharge scroll case are founded using highquality cast iron and rosin model, having small distortion after strict anneal dispose. Statorwith high precision and high coaxial can insure stable operation of rotor assembly.

Impeller:Based on the requirement, casting-impeller and welding-impeller are adopted. Castingimpeller is precisely cast with high strength aluminum-alloy. And the welding-impeller iswelded of a hub ,cover and wanes ,in the course of welding, heat treatment should be doneseveral times to eliminate welding stress. Each single impeller is dynamically balanced andtested with high speed after precisely machining.

Rotor:Rotor is consists of impellers, main shaft, shaft sleeve, half coupling and so on. Themain shaft makes use ofthe high quality carbon-steel, and carries through quenching andtempering. After assembly, the rotor was dynamically balanced to ensure steady and reliablerunning.

MC Series Multi-stage Centrifugal Blower-Cast Iron Structure is an efficient blower product with advanced level in the world, which is developed by importing American technology. This series of product use a number of patented technology, Compared with domestic products, we have obvious advantages in low noise, low vibration and high efficiency.

Feature:

Blower casing and return vanes are optimally designed to match the impeller sufficiently,lower flow losses as it is streamline designed.

Combined Impeller's aerodynamic efficiency is high by applying ternary flow meridian plane and compound profile technology.

Inlet guide rings are provided for impeller to improve its fluidity.

Aerofoil style return vanes design getting higher converting efficiency of static pressure energy and lower flow losses.

Blower performance is optimized by applying fluid-analysis technology and its polytropic efficiency up to 78%.

The requirement of both 50Hz and 60Hz can be fulfilled on the same blower.

Wider adjustable range and better performance.

Impeller is strictly dynamic balanced, lower vibration and higher reliability.Low noise.

Blower structure is advanced and reasonable, less wearing parts, convenient installation, operation and maintenance.