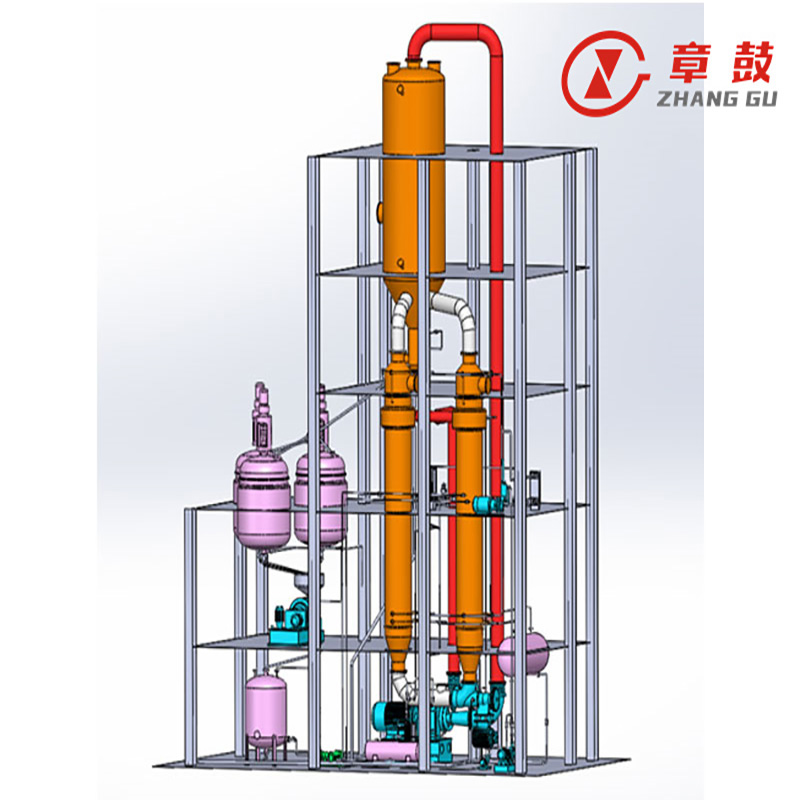

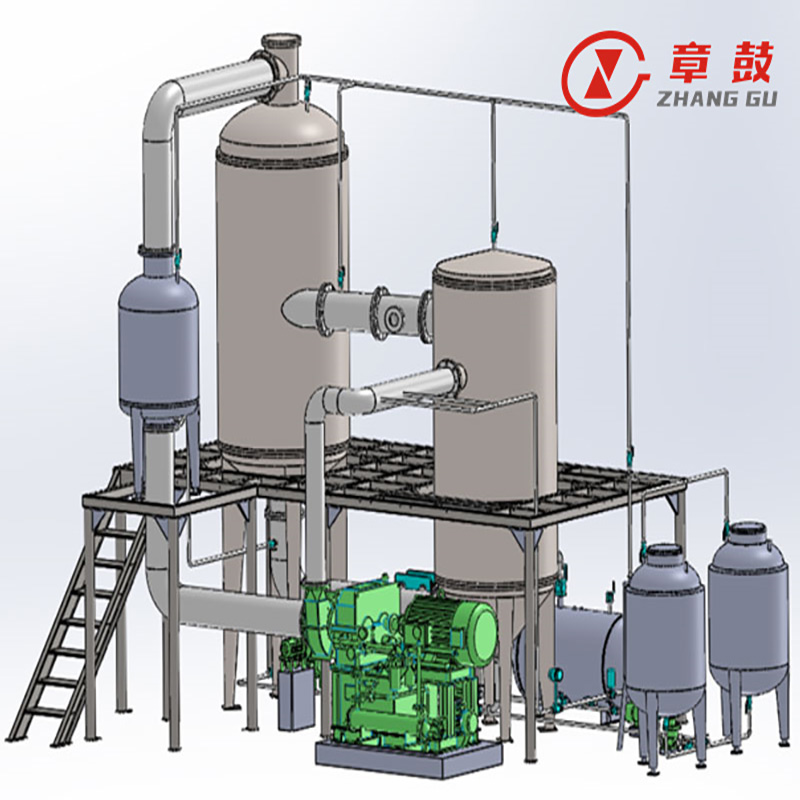

MVR Evaporation Concentration And Crystallization System

High Energy Savings: Recycles secondary steam in a closed loop, eliminating the need for external fresh steam and significantly reducing operating costs.

Environmentally Friendly: No boilers or fuel combustion required, cutting CO₂, SO₂, NOx, and particulate emissions.

Compact & Low Infrastructure Demand: Small footprint and minimal auxiliary equipment compared to traditional evaporators.

Safe for Heat-Sensitive Materials: Low-temperature evaporation (~40 °C) preserves product quality and prevents thermal degradation.

Low Maintenance & Easy Control: Few moving parts, simple layout, and fully automated operation.

Shandong Zhanggu Energy Saving and Environmental Protection Technology Co., Ltd. is a joint venture company established by Shandong Zhangqiu Blower Co., Ltd. and Technical Institute of Physics and Chemistry CAS. It is an engineering company specializing in the research and implementation of MVR (mechanical vapor recompression) evaporation concentration crystallization technology.

Since its establishment, the company has always firmly believed that leading technology is the key to the company's development, superior quality is the core of the company's survival, and timely and perfect after-sales service is the hub of the company's progress. The company introduces the mature and perfect MVR technology of Technical Institute of Physics and Chemistry CAS, as well as the long-term technical support of professors and experts of the Chinese Academy of Sciences, which ensures that the technical level of our company's MVR system is in the leading position in the industry.

The company has a number of independent R & D and manufacturing systems. Among them, the core equipment of MVR system-Roots steam compressor and centrifugal steam compressor have been operating safely and stably in many user sites for many years. Compared with other company products on the market at present, they have the advantages of high processing accuracy, long service life, simple structure and easy maintenance, high efficiency, energy saving and environmental protection. In the majority of users to establish a good reputation and credibility.

Over the years, the company has been committed to the promotion and application of MVR technology, and has widely explored the Chinese market. At present, MVR technology has been skillfully applied in medicine, chemical fiber, metal smelting and salt chemical industry. With Tongling Nonferrous Metals Group Zhangjiagang United Copper Co., Ltd., Sinochem DSM Pharmaceutical (Zibo) Co., Ltd. and other well-known domestic enterprises to maintain long-term good cooperative relations.

Since its establishment, the company has been constantly improving itself, actively learning and absorbing advanced technology at home and abroad; striving to innovate and continuously improving process design in combination with project engineering. Shandong Zhanggu Energy Saving and Environmental Protection Technology Co., Ltd. will always provide customers with high-quality systems, products and services with first-class technical strength, strict quality assurance measures and timely and perfect after-sales service.

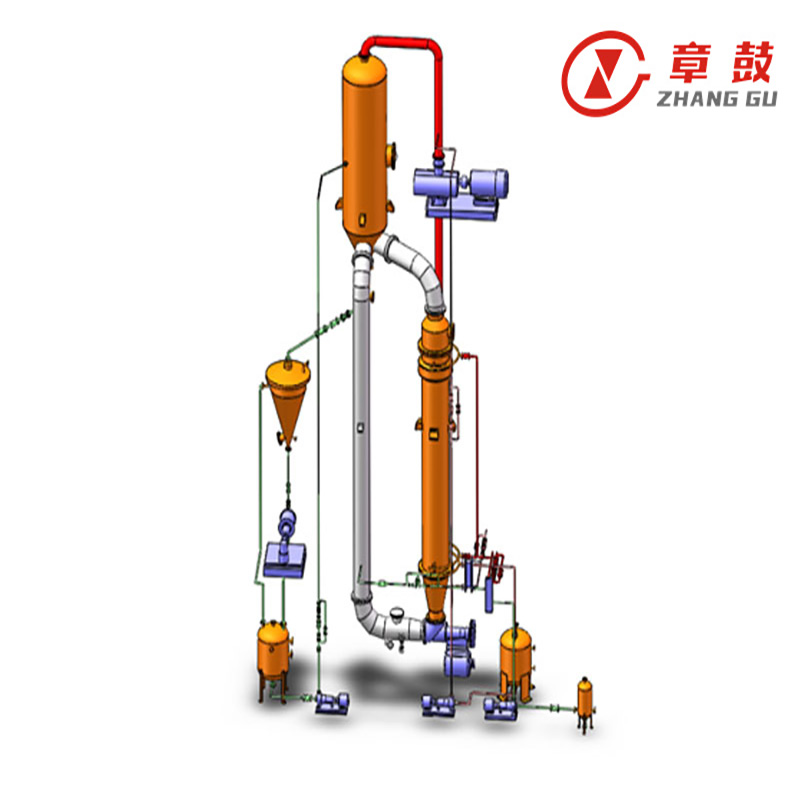

MVR Technology Principle

MVR stands for Mechanical Vapor Recompression technology. It compresses the secondary steam generated by the evaporator using a steam compressor, converting electrical energy into thermal energy to increase the steam temperature and enthalpy. The steam is then returned to the heat exchanger as the heating source to reheat and evaporate the feed liquid, thereby reducing the demand for external energy. This is an energy-saving and environmentally friendly technology.

MVR mechanical vapor recompression technology is a closed-loop system. At startup, a small amount of fresh steam is used to heat the material to boiling and generate secondary steam. Once secondary steam is produced, the supply of fresh steam is cut off. The secondary steam from the evaporator is separated by a vapor-liquid separator, then drawn into the steam compressor for recompression. This increases the pressure and enthalpy of the secondary steam, which is then used as the heating source in the heat exchange system for repeated utilization. The entire system produces no waste steam. Compared with traditional evaporation processes, the energy-saving effect is remarkable. By recycling steam, no further input of external fresh steam is needed, thus achieving both energy conservation and environmental protection.

In the MVR process flow diagram on the right, the secondary steam from the evaporator is compressed by the compressor, raising its temperature, pressure, and enthalpy. It is then sent to the heat exchanger as the heat source for evaporating the solution, making full use of the latent heat of the steam. Steam that would otherwise be wasted is fully utilized, its latent heat is recovered, and thermal efficiency is improved.

MVR Technology Features

Environmentally Friendly & Energy Saving

MVR compresses and reheats the secondary steam generated within the system and reuses it in a closed cycle to achieve evaporation, concentration, and crystallization. It does not require external fresh steam, and thus eliminates the need for boilers, fuel gas, cooling water, etc. As long as electricity is available, the system can operate normally, completely removing dependence on boilers. This reduces the pollution and emissions of CO₂, SO₂, nitrogen oxides, and solid particulate residues.

During operation, apart from the startup phase where electric heating or fresh steam is used, the MVR system requires no additional auxiliary heating. The condensate water produced after heat exchange of the secondary steam can also be recovered and reused. Therefore, MVR is a technology that saves energy and reduces consumption. Energy-saving performance can be seen in the “Energy Consumption Comparison Table” on the next page.Small Footprint & Fewer Utility Support Facilities

The MVR system eliminates the need for boilers, pipe networks, cooling towers, and other external auxiliary equipment. With a compact structural layout, its footprint is only 50% that of traditional evaporators.Reduced Risk of Pipeline Blockage

Traditional evaporation systems often use multi-effect evaporation, with large temperature differences between stages. The long residence time of the feed liquid in the piping increases the risk of blockage. In contrast, the MVR system is compact, has a short material flow path, operates at low evaporation temperatures, and has a small temperature difference, greatly reducing the risk of blockage.Suitable for Evaporation & Crystallization of Heat-Sensitive Materials

MVR evaporation technology can achieve low-temperature evaporation at around 40 °C, minimizing thermal degradation of heat-sensitive materials prone to denaturation at high temperatures, thus ensuring the quality of the crystallized product.Easy Operation & Control

The MVR system has few moving parts, short material flow paths, and fewer control points, enabling fully automated, unattended operation.

Comparison of MVR Evaporation Process and Traditional Evaporation Process Energy Consumption

Energy Saving Analysis

| Energy Consumption (Evaporation of 1 ton of water) | Evaporation Pan (1.5 tons steam) | Single-Effect Evaporator (1.2 tons steam) | Triple-Effect Evaporator (0.5 tons steam) | MVR System (30–80°C) |

Operating Cost (Coal-fired boiler 180 RMB/ton) | 270 RMB | 216 RMB | 90 RMB | 21–56 RMB (0.7 RMB/kWh) |

Energy Saving (Compared with MVR system) | 80%~92% | 74%~90% | 38%~77% | |

Operating Cost (Gas-fired boiler 350 RMB/ton) | 525 RMB | 420 RMB | 175 RMB | 21–56 RMB (0.7 RMB/kWh) |

Energy Saving (Compared with MVR system) | 89%~96% | 87%~95% | 68%~88% |

Environmental Protection Analysis

| Industry Using Evaporators | Annual Steam Consumption (10,000 tons/year) | Coal Saved Using MVR (10,000 tons/year) | CO₂ Emissions Reduced Using MVR (10,000 tons/year) | SO₂ Emissions Reduced Using MVR (10,000 tons/year) |

Food & Beverage | 8800 | 1760 | 4611 | 15 |

Environmental Protection | 9000 | 1800 | 4716 | 15.3 |

Dairy | 8000 | 1600 | 4192 | 13.6 |

Chemical | 10000 | 2000 | 5240 | 17 |

Pharmaceutical | 5000 | 1000 | 2620 | 8.5 |

Brewing | 6600 | 1600 | 4192 | 13.6 |

Alternative Fuels | 5000 | 1000 | 2620 | 8.5 |

Beverage Industry | 9500 | 1900 | 4978 | 16 |

Total | 63300 | 12660 | 33169 | 107.5 |

Forward-Looking Research, Leading Technology, Reliable Design

The Technical Institute of Physics and Chemistry of the Chinese Academy of Sciences, as one of the leading MVR technology research teams in China, has undertaken most of the national scientific research projects in this field, including more than 20 programs such as the National High-Tech R&D Program (863 Program), the National Key Technologies R&D Program, and major national science and technology projects. It has obtained multiple related patents.

Core Equipment

The core equipment of the MVR system—the steam compressor—is independently developed, designed, and manufactured by the company. With precise thermodynamic performance calculations, structural design for high-temperature-difference operating conditions, dedicated and reliable mechanical seal structures, and corrosion protection methods such as coatings, stainless steel, or titanium materials depending on operating conditions, combined with strict manufacturing precision and quality assurance measures, the steam compressor is ensured to operate reliably and stably.

MVR System Roots Steam Compressor | MVR System Centrifugal Steam Compressor |

|  |

MVR System Application Fields

Coal Chemical Industry: Concentration of high-salinity wastewater, high-concentration organic wastewater, high-concentration inorganic wastewater, and high-ammonia-nitrogen wastewater.

Chlor-Alkali Chemical Industry: Concentration of high-salinity wastewater, high-concentration organic wastewater, high-concentration inorganic wastewater, and high-ammonia-nitrogen wastewater.

Salt Chemical Industry: Salt chemical processes, potassium salt crystallization, and sodium sulfate production.

Chemical Fiber Industry: Concentration and reuse of saline solutions in production processes.

Electroplating and Surface Treatment: Concentration of high-salinity wastewater.

Pharmaceutical Industry: Concentration of traditional Chinese medicine preparations, low-temperature concentration of Western medicine, and vitamin preparation concentration.

Pesticide Industry: Concentration of high-salinity wastewater, high-concentration organic wastewater, high-concentration inorganic wastewater, and high-ammonia-nitrogen wastewater.

Printing, Dyeing, and Dye Industry: Concentration of high-salinity wastewater, high-concentration organic wastewater, high-concentration inorganic wastewater, and high-ammonia-nitrogen wastewater.

Metallurgical Industry: Concentration of high-salinity wastewater and acid recovery from H₂SO₄, HNO₃, or HCl refining units.

Petrochemical Industry: Removal of calcium and magnesium ions from wastewater to achieve zero discharge.

Rubber Production Industry: Concentration of high-salinity wastewater.

Landfill: Leachate evaporation and concentration.

Fragrance and Flavor Industry: Concentration of high-salinity wastewater, high-concentration organic wastewater, high-concentration inorganic wastewater, and high-ammonia-nitrogen wastewater.

Food and Beverage Industry: Crystallization and concentration of MSG, starch, sugar; concentration of fruit juices and beverages; concentration and purification of waste liquids.

Dairy Industry: Yogurt concentration and milk powder crystallization.

Brewing Industry: Alcohol distillation, wine, and beer production.

Pulp and Paper Industry: Black liquor concentration, bleaching effluent concentration and purification, and crystallization recovery of NaCl and Na₂SO₄.

Seawater Desalination

Customer Sites

The MVR technology developed by the Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, has been successfully operating for many years across various industries and numerous users. It is stable, reliable, and delivers remarkable energy-saving performance.

Quality Service Commitment

Our company implements the “Three Guarantees” policy within the warranty period: repair, replacement, or return, depending on the specific situation.

For products beyond the warranty period, we provide lifetime service — charging only for parts, with no labor fees.

For all customers who purchase our products, we offer free training as well as guidance for installation and commissioning.