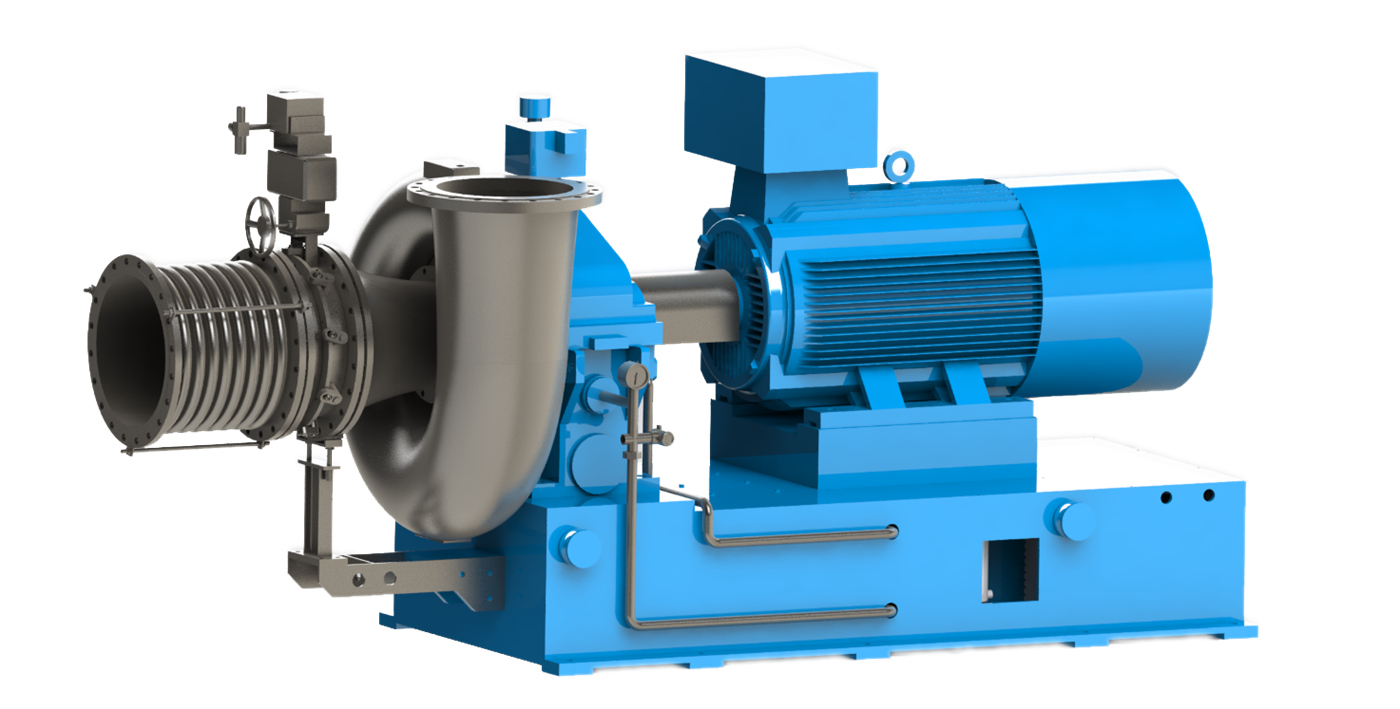

Turbo Vacuum Pump

1.Applying ternary theory design with high efficiency of 82%

2.Applying axial inlet guide vanes and a diffuser regulating device, flow regulation range can be the 45% to 110% of the rated flow, and get the higher efficiency in the off-rating operation conditions.

3.Applying integral structure design, blower body is assembled on the casing of the gear box, lubricating system, motor, and gear box are assembled on a common base which is also used as oil tank.

4.Applying strict dynamic balance to get low vibration, low noise, and high reliability.

5.Applying advanced blower structure design to make an easy installation, operation and maintenance. PLC to realize real time monitoring for the blower running, the vibration and temperature of the bearings, anti-surge control, the start of interlock protection, trouble alarm, lubricating oil pressure, and oil temperature control.

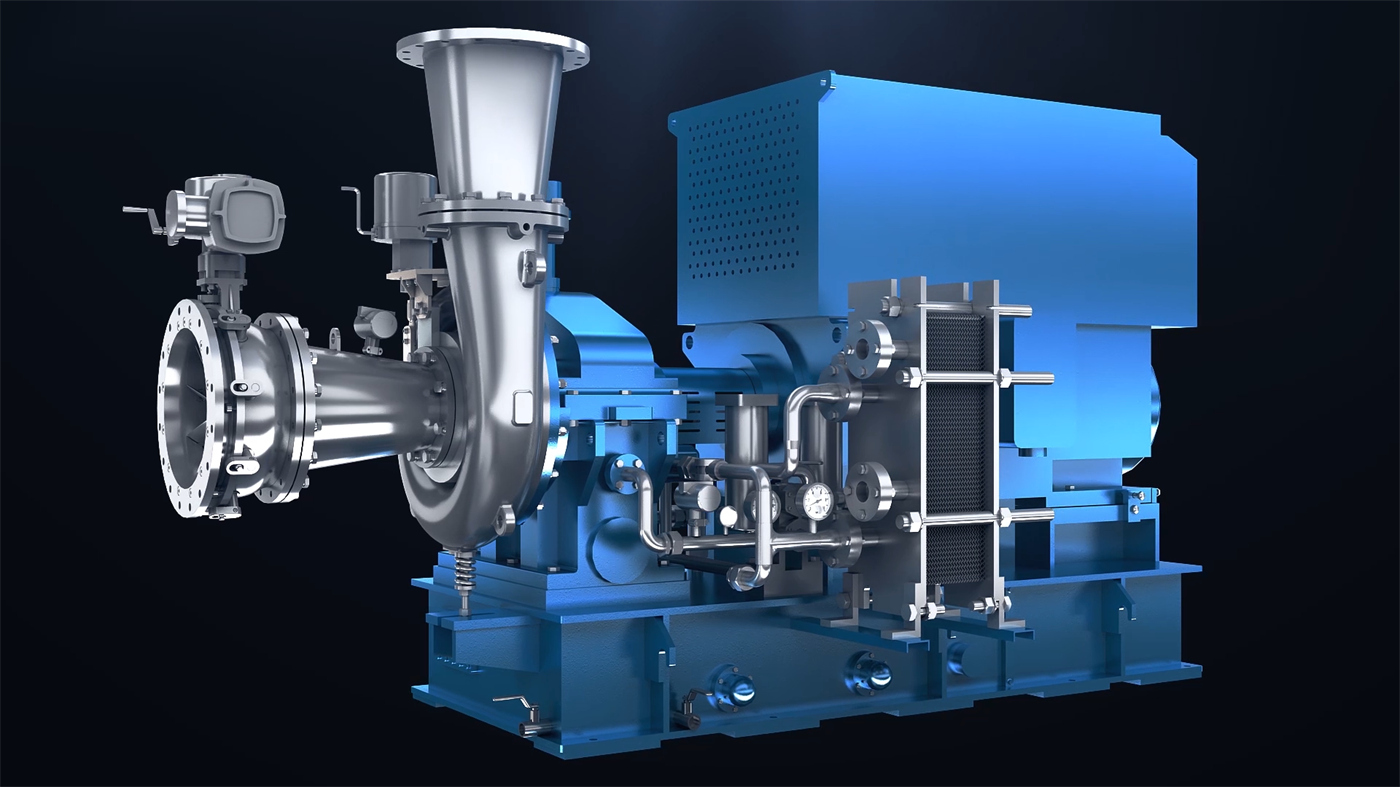

Geared Turbo Vacuum Pump

Geared Turbo Vacuum Pump is developed by technical authority of Beijing University of Aeronautics and Astronautics. Integrating all resources those representing the highest level of aerospace field in China in the Research, Technology, Production, Manufacturing. ThisGeared Turbo Vacuum Pump’s aerodynamic performance and structure design achieves the worldwide advanced technology level.

High-speed Geared Turbo Vacuum Pump is a new product jointly designed by Shandong Zhangqiu Blower Co., Ltd. and Xi'an Jiao Tong University. The pneumatic performance and structural design of this product series have reached the advanced level of comparable products both domestically and internationally. These vacuum pumps are widely used in sewage water treatment, metallurgy, fluidization of circulating fluidized bed boilers in power stations, exhaust gas desulfurization, pharmacy, gas boosting, and other applications.

Features:

1.Applying ternary theory design with high efficiency of 82%

2.Applying axial inlet guide vanes and a diffuser regulating device, flow regulation range can be the 45% to 110% of the rated flow, and get the higher efficiency in the off-rating operation conditions.

3.Applying integral structure design, blower body is assembled on the casing of the gear box, lubricating system, motor, and gear box are assembled on a common base which is also used as oil tank.

4.Applying strict dynamic balance to get low vibration, low noise, and high reliability.

5.Applying advanced blower structure design to make an easy installation, operation and maintenance. PLC to realize real time monitoring for the blower running, the vibration and temperature of the bearings, anti-surge control, the start of interlock protection, trouble alarm, lubricating oil pressure, and oil temperature control.

Applications:

Widely used in sewage water treatment, metallurgy, boiler fluidization, gas desulfurization, pharmacy, gas boosting etc. industries.

Main structure

Guide Vane Controller

The Guide Vane Controller is installed in front of the impeller. It consists of casing, guide vane, impeller cover, electric actuator, adjustable diffuser, etc. The clearance between the impeller cover and the impeller ensures stable operation of the blower. The angle of the guide vane is adjusted by the electric actuator, which causes the airflow to pre-rotate before entering the impeller. The use of an adjustable diffuser allows the blower to operate over a wider range.

Impeller

The impeller design is based on ternary flow theory, offering high efficiency. Each impeller is dynamically balanced after precision machining, and all impellers undergo testing at 1.15 times the rated speed and pass strength tests. To meet the requirements of different conditions, impeller materials are available in options such as cast aluminum, forged steel, and stainless steel.

High-speed Rotor

The high-speed rotor consists of the impeller, the high-speed gear, and the high-speed shaft. The impeller and high-speed shaft are connected by a rod, and torque transmission is achieved via end pins. Dynamic balancing tests are performed in accordance with international standards, with precision reaching G1 grade to ensure smooth and reliable operation.

Volute Casing

This part adopts a round-section volute casing. The profile line of the scroll wall is designed as a logarithmic spiral, which conforms to the airflow laws of motion and imposes low impact on the blower. As a result, the blower achieves high flow efficiency, low vibration, and low noise.

Gear

The acceleration gear pair adopts an involute tooth profile. The surfaces of the gearwheel and pinion are ground and nitride-hardened to ensure high-speed stable operation, low vibration, and low noise. The lifetime can reach 20 years.

Bearing

The high-speed shaft support uses tilting pad journal bearings composed of multiple flexible pads. The pads can pivot around a fulcrum, providing excellent anti-vibration performance and the ability to automatically adjust according to variations in load and speed.

Seal

This part adopts a split-type labyrinth seal structure, which can be replaced without dismantling the impeller. It offers effective airtightness and is easy to replace.

About Us

Shandong Zhangqiu Blower Co.,Ltd (Formerly name: Shandong Zhangqiu Blower Works) is a company with over 50 years’ blower design, manufacture technology and experience. We set up two Sino-Japanese Joint-ventures and one USA branch that of 1st company in China blower industry establishing oversea branch. We are the leading enterprise in Zhangqiu local industry and main product-Roots Blower’s market occupancy is top-ranked in China blower industry.

Overall developing strategy: “Develop main business, pioneer new fields and innovate, cooperate to be a great company”. Working concept: “Do the best”. Now we are a modern company integrated the design, manufacturing and sales on products of: Roots Blower, Centrifugal Blower, Fan, Industrial Pump, Pneumatic Conveying System, Electrical Equipment, MVR Evaporation, Concentration and Crystallization system, Waste Water Treatment Product and Service and etc.

In 2005, we moved to newly built high-standard modern industrial park. This new industrial park covers an area of 430,000 m2 with complete facility and magnificent office building providing wide developing space for cooperation with oversea company and great-leap-forward development of us.

In July, 7th, 2011, the company was publish listed on Shenzhen Stock Exchange center. Stock code: 002598. This is a great development milestone of us.