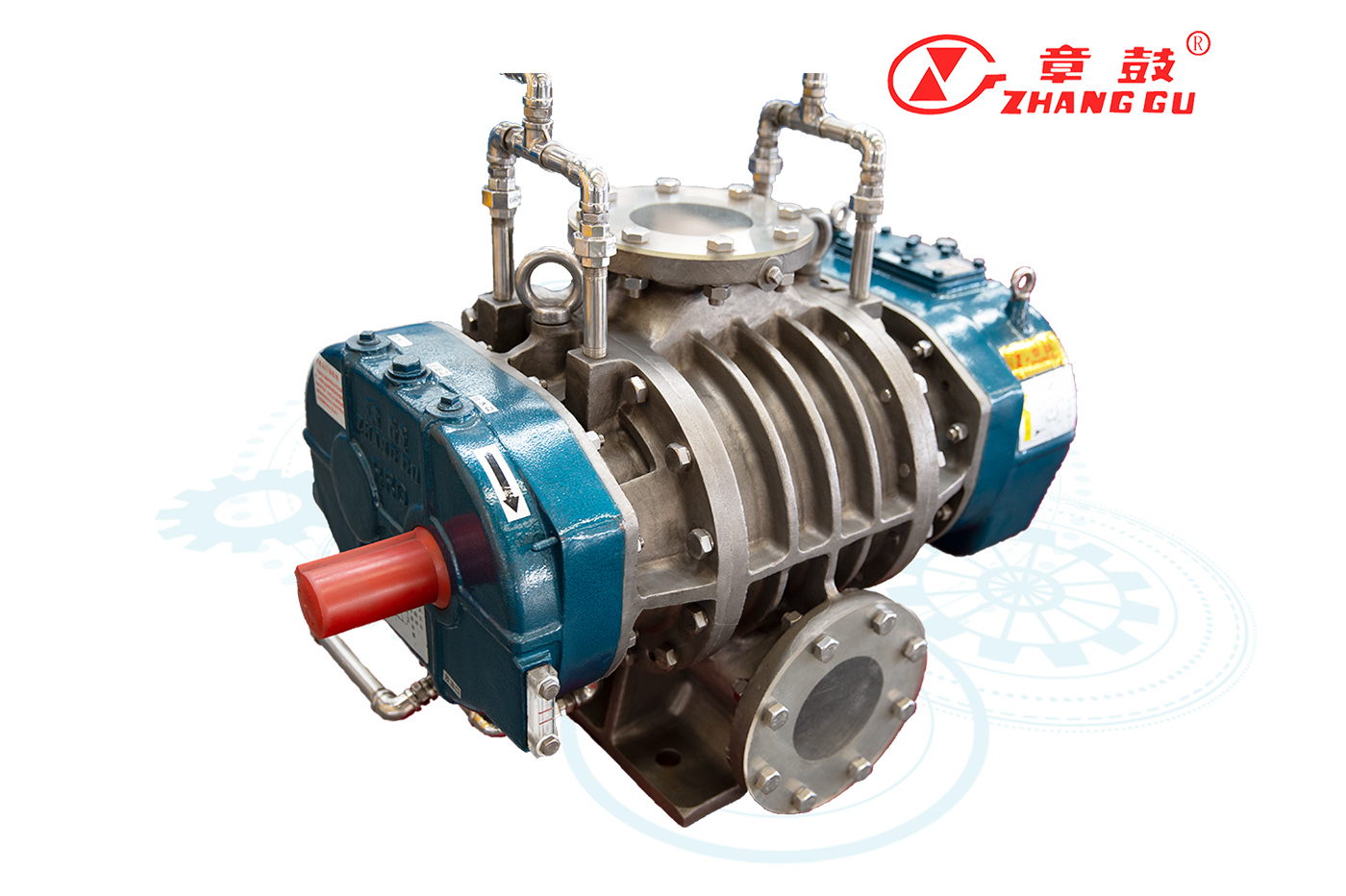

oil free screw compressor

1.Large range of capacity and pressure rise and wide application that can be chosen conveniently by users.

Evaporation Capacity :30-7400KG, Temperature Rise: 10-25℃

2.Various transmission modes are adopted by compressor and motor that ensure the stability of the operation. Simple structure, easy maintenance.

3.Patent impeller profile to ensure reliable seal performance, high efficiency and energy saving.

4.High machining accuracy, reliable operation, long service life

5.No lubrication inside the casing, and the design structure ensures that lubricating oil and steam will not mix up.

6.Compressor shaft seal can be chosen according to user requirement. Various seal type with good effect to ensure zero leakage of conveying steam.

7. Perfect material of compressor wetted parts is available to meet user requirement according to different transfer medium.

The company specializes in the production of Roots blowers, possessing robust R&D and manufacturing capabilities. Beyond focusing on product development, production, and sales, the company has established a comprehensive after-sales service system. Our VR series Roots steam compressors feature high efficiency, energy savings, and smooth operation. This product line is widely applicable in MVR systems for evaporation crystallization and evaporation concentration industries.

Ordering Instructions

1. The inlet steam flow rate specified in the VR series Roots steam compressor catalog parameters refers to the flow rate when sucking saturated steam at 80°C. If the user's conveyed medium conditions differ from those in the catalog, please contact our technical department at zhanggu_fys@163.com.

2. We offer multiple material options including carbon steel, 304, 316, 316L, duplex stainless steel, titanium, and special corrosion-resistant coatings for customer selection.

3. When ordering, please specify the conveyed medium, inlet flow rate, inlet temperature, and required pressure increase or temperature rise. If the catalog performance parameters do not meet your requirements, please contact our technical department. We can customize special specifications of Roots steam compressors according to customer requirements.

Introduction to MVR Technology

MVR stands for Mechanical Vapor Recompression technology. It is an energy-saving technique that compresses the secondary vapor generated by an evaporator using a vapor compressor, thereby increasing the vapor's temperature and enthalpy. This compressed vapor is then returned to the heat exchanger to serve as a heating source, reducing the demand for external energy.

MVR Mechanical Vapor Recompression technology operates as a closed-loop system. During startup, a small amount of initial fresh steam is used for heating. After the material is heated to boiling and generates secondary steam, the fresh steam supply is cut off. The secondary steam produced by the evaporator is separated by a gas-liquid separator, then drawn into the steam compressor for recompression. This process increases the pressure and enthalpy of the secondary steam, which is then reused as a heating source in the heat exchange system. The entire system produces no waste steam. Compared to traditional evaporation systems, the energy-saving effect is remarkably significant. By recovering steam, the system eliminates the need for external fresh steam input, achieving both energy conservation and environmental protection.

The core component of the MVR system is the steam compressor. Mature compressor types primarily include centrifugal compressors and Roots compressors. Roots steam compressors operate on the same principle as conventional Roots blowers, but they transport steam within the system. Taking water vapor as an example, Roots steam compressors can provide an effective temperature rise of 10–25°C, making them suitable for applications with low evaporation rates but significant boiling point elevation requirements.

The diagram below illustrates the MVR process flow. Secondary steam exiting the evaporator is compressed by the compressor, increasing its temperature, pressure, and thermal enthalpy. This compressed steam is then directed to the heat exchanger to serve as the heat source for evaporating the solution, fully utilizing the latent heat of the steam. The steam, which would otherwise be discarded, is thus fully utilized, recovering latent heat and improving thermal efficiency.

About us

Shandong Zhangqiu Blower Co., Ltd. possesses nearly fifty years of expertise in blower design, production, and manufacturing technology. It has evolved into a modern, large-scale mechanical processing enterprise integrating the design, production, and sales of products including Roots blowers, vacuum pumps, centrifugal fans, industrial pumps, industrial water treatment engineering and equipment, heavy machinery, complete pneumatic conveying systems, electrical equipment, MVR evaporation concentration and crystallization technology, and complete systems. The company successfully listed on the Shenzhen Stock Exchange on July 7, 2011, with stock code: 002598.

The company holds Level II Safety Production Standardization certification and has obtained ISO9001 Quality Management System certification, ISO14001 Environmental Management System certification, Occupational Health Management System certification, and National Military Standard System certification. Relevant products have passed Mine Product Safety Mark certification, CE certification, Energy Efficiency certification, and production licensing. The company has successfully undertaken multiple national, provincial, and municipal-level technological innovation projects. Several products have been included in the national “Spark” Program, provincial key projects, and national new product development initiatives.

Application fields