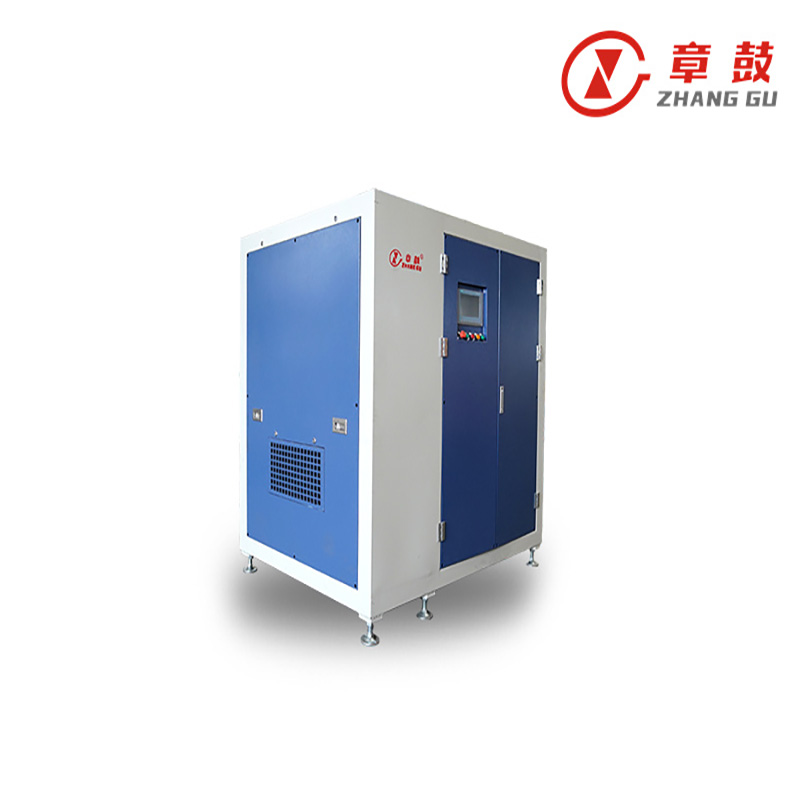

Air Suspension Blower

Air bearing: When rotating, air flow occurs on the surface of the shaft, generating pressure and forming an air film. As the rotational speed increases, the shaft will float. Advantages: 1. No contact or friction, high efficiency; 2. No lubricating oil is required.

Impeller: High-efficiency backward-curved impeller; Optimized assembly technology enhances efficiency and adjustment range. Five-axis linkage CNC machining ensures the precise representation of the design profile and excellent durability design.

Motor: During high-speed rotation, the patented self-circulation cooling technology ensures efficient operation. The design is simple and elegant, ensuring excellent durability even under extreme working conditions. Induction motors and permanent magnet synchronous motors are provided.

Shandong, Zhanggu has successfully developed Shandong Zhanggu Air Foil Bearing Suspension Vacuum Pump products by combin.ing 6 core technology: the fourth generation of multi-simply supported beam dynamic pressure air suspension bearing technologyhigh power density permanent magnet synchronous motor technology, wide working condition high-performance aerodynamicdesign method, high-speed rotor dynamic design method, thermal management design technology and eficient drive controltechnology. lt has the characteristics of high efficiency, low noise, oil free, maintenance free and long lifeShandong Zhanggu Air Foil Bearing, Suspension Vacuum Pump can be used in paper-making industry, printing industry, blistelindustry,ceramic industry,electronics industry and so on.

Foil bearing has physical contact between therotor and the bearing before starting, the relativemovement of the rotor and the bearing generates airpressure when starting, when the rotor rotates, thespeed of the air around the rotor can be convertedinto pressure energy, and the air pressure makes therotor float when the rotor reaches a certain rotationspeed and plays a lubricating role.

The high-speed rotordynamic design method is a key technology to ensure the stable operation of the rotor at highspeed, which is closely related to the rotor structure and bearing stiffness, and is highly coupled with the motor design,aerodynamic design and bearing design.

The R&D team has applied the thermal management design and optimization technology of the secondary air system of aero-engines across borders, forming unique design technology and products.

Company Factory

Shandong Zhangqiu Blower Co., Ltd. boasts nearly fifty years of expertise in fan design, production, and manufacturing. Over the years, it has evolved into a modern large-scale machinery enterprise that integrates the design, production, and sales of Roots blowers, vacuum pumps, centrifugal fans, industrial pumps, industrial water treatment projects and equipment, heavy machinery, pneumatic conveying systems, electrical equipment, as well as MVR evaporation, concentration, and crystallization technologies and complete systems.

The company is a second-level enterprise in terms of safety production standardization. It has passed ISO9001 quality system certification, ISO14001 environmental management system certification, occupational health management system certification, and national military standard system certification. Its related products have obtained the safety mark for mining products, CE certification, product energy-saving certification, and production license. The company has successfully undertaken many national, provincial and municipal technological innovation plans on multiple occasions. Many of our products have been included in the national "Spark" Program, provincial key projects and national new product plans.