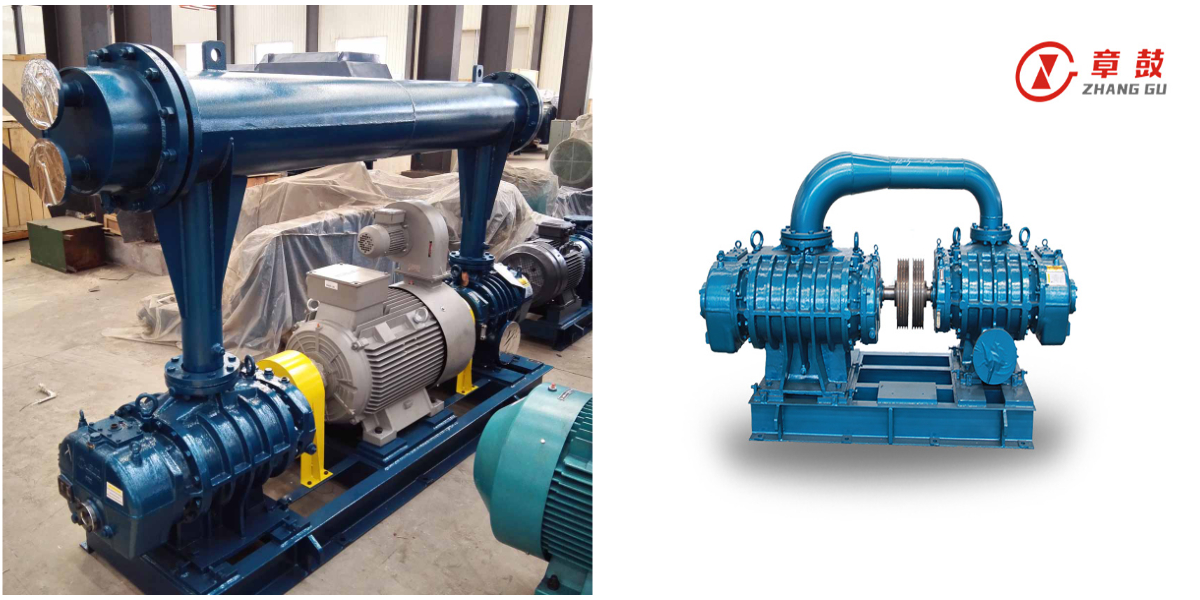

RR Series Roots Blower Pump

Blowers are key equipment in chemical production, with their main functions focused on gas handling and material conveying. Its core applications include: providing uniform gas flow for fluidized bed reactors, allowing solid materials to be fully fluidized and ensuring that chemical reactions are carried out efficiently; Through the pneumatic conveying system, the powder and granular raw materials are safely transported in the closed pipeline; circulate and pressurize the process gas to maintain the micro-positive pressure of the system and prevent harmful gas leakage; Exhaust gases are also blown into environmentally friendly treatment units (e.g. RTOs). Because chemical media often have corrosive, flammable and explosive characteristics, it has extremely high requirements for equipment sealing, explosion-proof and material corrosion resistance.

The more important application of the blower is the purification and purification link after the biogas is produced. To convert biogas into biogas (BNG), CO₂ (carbon dioxide) is removed. In the decarburization process of membrane separation, the blower is crucial. It first pressurizes the raw material biogas and then passes it through a series of hollow fiber membrane groups. Gases such as CO₂ are preferentially separated through the membrane wall, while methane is retained and concentrated due to its low permeability. In this process, the stable pressure and airflow provided by the blower are key to ensuring separation efficiency and economy. In addition, the blower is used to supply combustion air to the biogas flare (burner) to ensure that excess biogas is burned safely and thoroughly.