Belt Driven Blower

Series B Single-stage High-speed Centrifugal Blower is a new product jointly designed by Shandong Zhangqiu Blower Co., Ltd. and Xi’an Jiao Tong University. The pneumatic performance and structural design of this product series have reached the advanced level of comparable products both domestically and internationally. These blowers are widely used in sewage water treatment, metallurgy, fluidization of circulating fluidized bed boilers in power stations, exhaust gas desulphurization, pharmaceuticals, gas boosting, and other applications.

Product Introduction

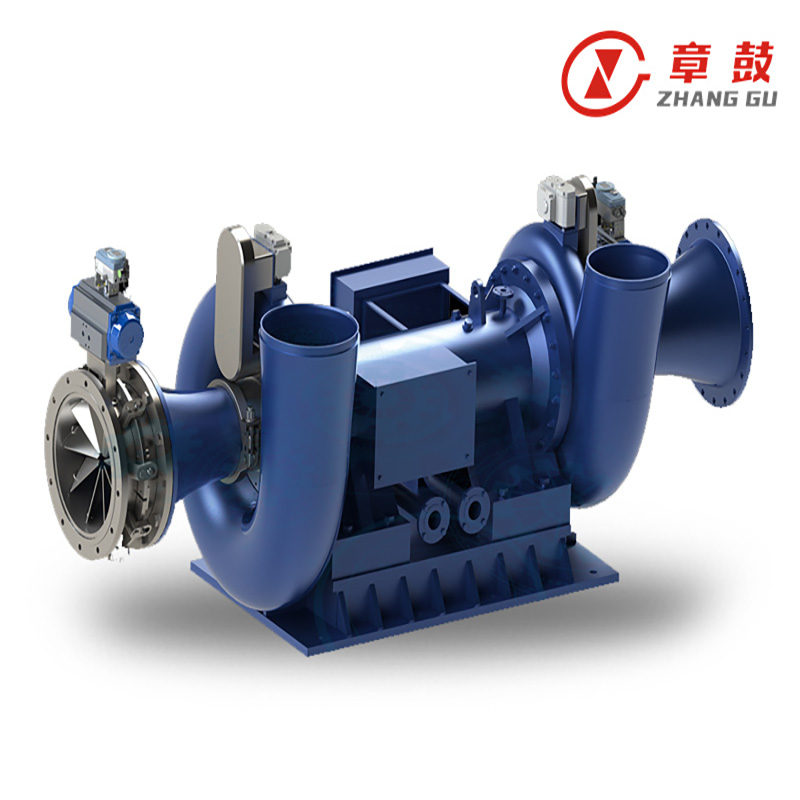

CB series High speed Turbo Blower is developed by Jiangsu Zhanggu Lipori Power Technology Co., Ltd., adopting advanced aero turbo machinery technology, based on the years' accumulated experience of Shandong Zhangqi Blower Co., Ltd.

This series products achieve advanced technology level both in China and abroad on pneumatic performance and structure design, and are widely used in wastewater treatment, power plant, petroleum, chemical, non-ferrous metallurgy, gas treatment, solid waste treatment.

Product Features

Advanced impeller profile curve and high efficiency

The ternary flow theory design of the impeller and the application of flow analysis technology forecasting performance of blower make the adiabatic efficiency reach up to 82%.

The flow capacity can be controlled in a wide range, and the blower can be applied to a variety of working conditions.

3 options on blower flow capacity adjustment: VFD, IGV (Inlet Guide Vane), OGV (Outlet Guide Vane), wide adjusting range and high efficiency maintained under non-rated working conditions. The provided anti-surge device can effectively prevent the surge problem.

The compact blower structure and small size

The blowers adopt an integrated assembly-type structure. Specifically, the blower body is assembled on the casing of the gear accelerating box, the lubricating oil system is distributed, and the motor and gear accelerating box are installed compactly on a common pedestal, which also serves as an oil tank.

After strict dynamic balance, the rotor exhibits low vibration, high reliability, and low overall noise.

The moment of inertia of the rotor is small, which decreases startup and stop time, and eliminates the need for a high oil level tank and accumulator. Compared to other blowers with the same flow capacity and pressure rise, this product offers lower energy consumption, lighter weight, and smaller size.

The structure of the blower is advanced and reasonable, with few easy-worn parts. Installation, operation, and maintenance are convenient.

High degree of intelligence

Parameters such as bearing vibration of the whole machine, temperature rise, inlet and outlet pressure and temperature, anti-surge control, interlock protection startup, failure alarm, lubricating system oil pressure, oil temperature control, etc., are managed by a programmable logic controller (PLC) for real-time monitoring. With fewer wearing parts, daily maintenance is convenient.

The bearing’s vibration, temperature, inlet and outlet pressure, temperature, anti-surge control, start-stop interlock protection, fault alarm, lubricating oil pressure, oil temperature, and a series of monitoring and control functions are handled by PLC. Data is transmitted in real-time to the "Zhanggu Cloud" intelligent cloud platform, allowing users to monitor equipment running status in real-time alongside project engineers.

Main structure

Guide Vane Controller | |

Impeller | |

High-speed Rotor | |

Volute Casing | |

Gear | |

Bearing | |

Seal |