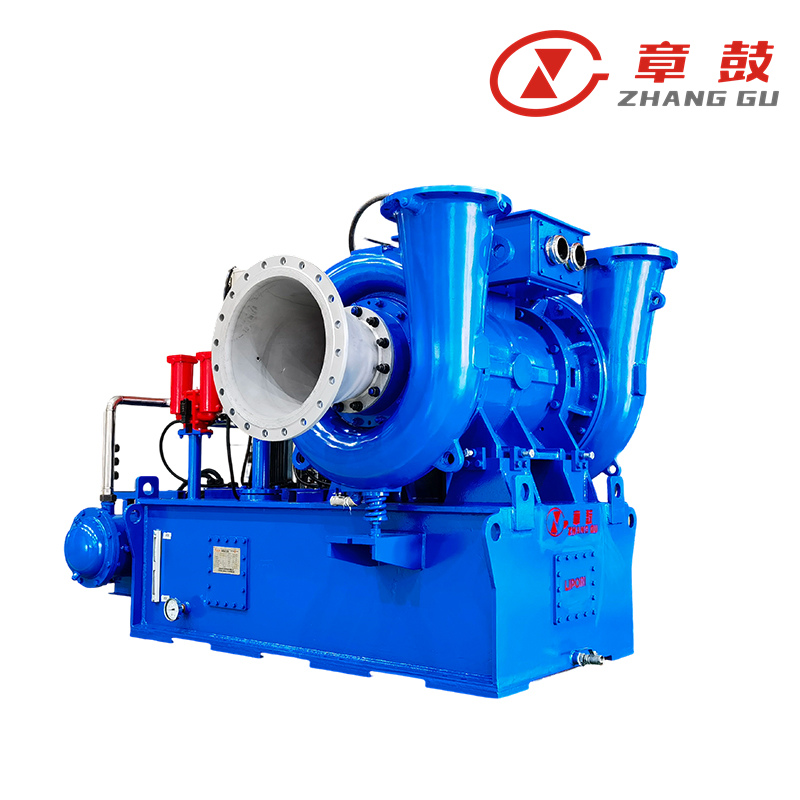

Chemical Vacuum Pump

CVP series high speed Turbo vacuum pump

High Efficiency & Energy Saving: Custom-designed impeller with 85% adiabatic efficiency, 20–45% more efficient than comparable pumps.

Wide Range & Stable Performance: Dual regulation (VFD/OGV) maintains stable vacuum under varying flow; anti-surge included.

Compact & Smart: Skid-mounted, space-saving design. PLC and cloud platform enable real-time monitoring and remote control.

Durable & Low Maintenance: Inlet separator protects impeller; high-efficiency PM motor reduces noise and energy use. Few wearing parts, easy upkeep.

CVP series high speed Turbo vacuum pump is newly developed product of high efficiency and power-saving based on the years' experience of Shandong Zhangqiu Blower Co., Ltd and the introduction of Beijing University of Aeronautics and Astronautics (Beihang University) professional doctor team.

The pneumatic performance and structural design of this series product has reached the leading level in China and abroad, customized design according to the field conditions, can be widely used in paper-making, foundry, alumina flat plate/vertical plate vacuum dewatering and other vacuum process. Also power-saving upgrading projects to replace water ring vacuum pumps.

Product Code

CVP means Turbo vacuum pump

1st number means suction rated flow capacity, unit: m³/min

2nd number means rated vacuum degree, unit: kPa

Multiple vacuum degree and flow capacity can be listed as per this example, just separate by "/"

D means direct drive, null means driven by gearbox

Number 2 means two stage blowers in series, null means single stage

Product Features

High Efficiency Advanced Impeller Profile Customized Design, Excellent Power-saving Performance

The impeller is designed by three dimensional flow theory, and the full three dimensional flow simulation. The performance of the Turbo vacuum pump is predicted by flow analysis technology, and the adiabatic efficiency of the steam compressor can reach about 85%. Its efficiency is about 20% ~ 45% higher than other vacuum pumps based on same vacuum degree and flow capacity.

The impeller is customized design according to the working parameters of the user to ensure that the working parameters required by the user are in the impeller efficient area, which is more energy saving.

Wide Adjust Range, Stable Vacuum Degree

Turbo vacuum pump flow capacity is wide and can be adjusted by two modes: VFD, OGV, ensures stable vacuum degree under large fluctuation of flow. Anti-surge device is provided to avoid surge problem effectively.

Compact Design, Less Footprint

The overall skid-mounted structure is adopted. Turbo vacuum pump body is directly connected with gearbox casing. The lubricating oil system, gearbox and the motor are arranged on the common base which serves as the oil tank. Two air end can be arranged for single unit blower to fulfill diverse vacuum degree requirement. Less weight and less footprint.

Low Noise Level

Through the advanced design technology of spiral case and impeller, the discrete noise and wide-band noise are suppressed, and the active control of aerodynamic noise is realized. More easily decayed.

Less Wearing Parts, Convenient Installation and Maintenance

Less wearing parts, less site maintenance, easy & fast installation.

High Degree of Intelligence

The bearing's vibration, temperature, the inlet and outlet pressure, temperature, anti-surge control, start-stop interlock protection, fault alarm, lubricating oil pressure, oil temperature and a series of monitoring and control system are controlled by PLC, and real-time transmission to the "Zhanggu Cloud" intelligent cloud platform, users can real-time monitoring equipment running status with project engineer.

Main structure

Regulating Mechanism

OGV device can be selected as per working condition. OGV is composed of diffuser disc, guide vane, transmission mechanism, actuator, etc., to ensure constant vacuum degree under flow variation, which will guarantee the system stability.

Inlet Separator

When the vacuum pump suction medium contains impurities, such as pulp, sand, grout, etc., the inlet separator developed by our company can effectively separate these impurities. This ensures the vacuum pump suction gas remains free of contaminants, avoiding impeller wear and scaling, and further safeguarding impeller efficiency and service life.

High-Speed Permanent Magnet Synchronous Motor

Permanent magnet synchronous motor is adopted as standard. This type of motor offers higher efficiency and meets Grade 1 energy efficiency according to the GB30253-2013 standard. Its rated operating efficiency reaches 94.5–97%, which is 4–6% higher than that of asynchronous motors. It also features a simple structure, smaller size, lower noise, and higher energy savings, especially during no-load operation.