compressed air knife

High Efficiency & Energy Saving: Advanced aerodynamic design and customized configurations ensure optimal performance with significant energy reduction.

Robust & Adaptive Design: Precision-engineered core components and multi-material options provide reliability under diverse operating conditions.

Intelligent Monitoring & Cloud Connectivity: Real-time data access, remote diagnostics, and instant alerts enable proactive maintenance and efficient operation.

Integrated & Compact System: Comprehensive auxiliary functions and flexible installation options minimize maintenance needs and simplify operation.

Product Introduction

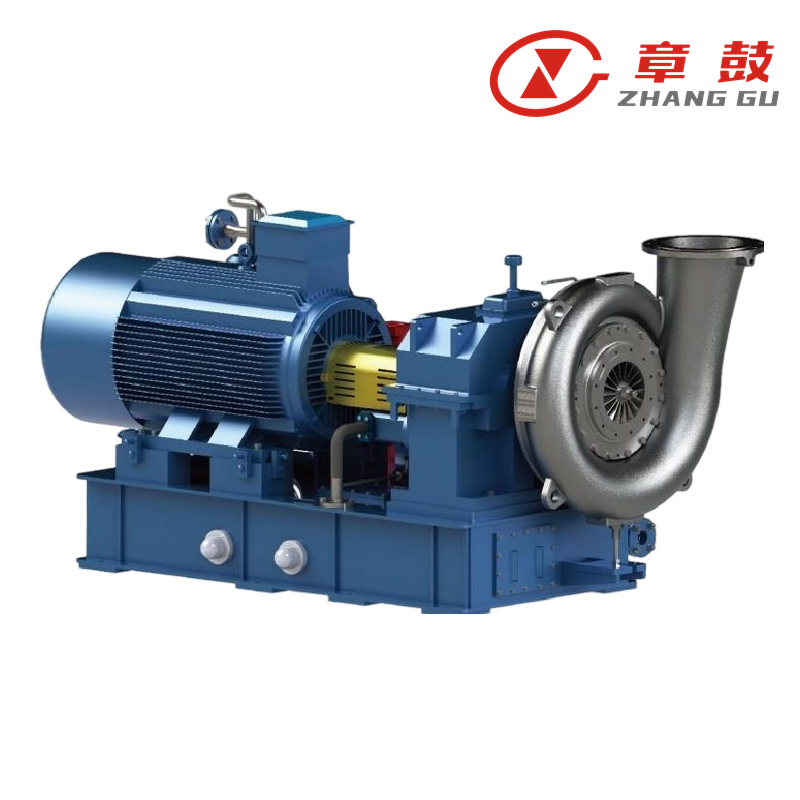

CBV High Temperature-rise Steam Compressor is a newly developed high-efficiency and energy-saving product. It leverages years of expertise from Shandong Zhangqiu Blower Co., Ltd. and incorporates advanced technology introduced by a professional doctoral team from Beihang University. The aerodynamic performance and structural design of this product series have reached leading domestic and international levels. Customized to suit specific field conditions, it can be widely applied in fields such as MVR system steam compression and positive-pressure steam transportation.

Steam Compressor Naming Rule

Example: CBV8.0-90/117-2D

CBV: Steam Compressor

8.0: Evaporation Capacity (Unit: t/h)

90: Evaporation Temperature (Suction Saturated Temperature, Unit: °C)

117: Discharge Saturated Temperature (Evaporation Temperature + Saturated Temperature Rise, Unit: °C)

2: Double Stage in Series (Blank indicates Single Stage)

D: Direct Drive (Blank indicates Gearbox Drive)

Main structure

Impeller

The high-efficiency impeller is designed using three-dimensional flow theory. After strict precision machining, it undergoes static and dynamic balancing calibration and passes an overspeed test at 1.15 times the rated speed to ensure strength and reliability. To meet various steam compressor operating conditions, the impeller can be manufactured from materials such as titanium, duplex stainless steel, and others.

Volute Casing

A circular-section volute is employed, with its wall profile designed as a logarithmic spiral to align with airflow dynamics, minimizing impact on the blower. This results in high flow efficiency, low vibration, and reduced noise. Depending on specific working conditions, the volute casing can be made from stainless steel grades including 304, 316L, 2205, or 2507.

High-speed Rotor

The high-speed rotor consists of the impeller, high-speed gear, and high-speed shaft. The impeller and shaft are connected via a rod, with torque transmitted by end-surface pins or spline teeth. Dynamic balancing is performed in accordance with international standards, achieving up to G1 grade precision to ensure smooth and reliable operation.

Gear

The acceleration gear pair features an involute tooth profile. Both the gearwheel and pinion undergo grinding and nitride-hardening treatments to ensure stable high-speed operation with low vibration and noise. The designed service life of the gears is 20 years.

Bearing

The high-speed shaft is supported by a tilting pad journal bearing composed of multiple flexible pads. These pads can pivot around their fulcrums, providing excellent anti-vibration performance and the ability to automatically adapt to variations in load and speed.

General structure

Seal

According to the requirements of working conditions, diverse options of sealing are available for the steam compressor. The standard options include: labyrinth seal with steam purging, carbon ring sealing with steam purging, dry gas seal, etc.

Sealing Steam Charging Device

The Sealing Steam Charging Device is used for negative pressure or normal working condition steam compressors. It charges superheated steam into the shaft seal to prevent air leakage into the compressor. The steam charging device includes a steam pressure relief valve, pressure detection device, stainless steel filter, and etc. For steam compressors under positive pressure conditions, pressure relief methods such as blow-off or steam extraction are usually used to prevent exposed steam from entering the gearbox, resulting in emulsification of lubricating oil.

Drainage Tank

Used for collecting and discharging the liquid water generated from the blower unit. It can be designed in negative pressure, normal pressure, or positive pressure modes as per actual requirements.

The tank body is equipped with an inlet valve (manual or automatic option), sight glass, liquid level gauge (local or remote transmission), drainage valve, and other accessories. If equipped with an automatic drainage valve or drainage pump (for negative pressure conditions) and remote transmission liquid level gauge, automatic drainage, real-time monitoring of liquid level, abnormal alarm, and other functions can be realized.

Intelligent Cloud Platform "Zhanggu Cloud"

Cloud computing plays a pivotal role in enterprise digitalization. It enables flexible and scalable on-demand allocation of information system resources, facilitates the standardization of technology and management within enterprise information systems, and provides enhanced support for operational efficiency.

Zhanggu Cloud utilizes advanced cloud technologies to achieve large-scale equipment networking, data transmission, cloud computing, and remote operation and maintenance functions. It allows users to monitor equipment quantity, distribution, fault alerts, operational history records, and more. Real-time data enables precise fault diagnosis, supports accurate solution recommendations for customers, and provides valuable reference for after-sales personnel. The platform also supports instant query of fault alarms, with SMS and WeChat notification features, ensuring engineers are promptly informed of device status.