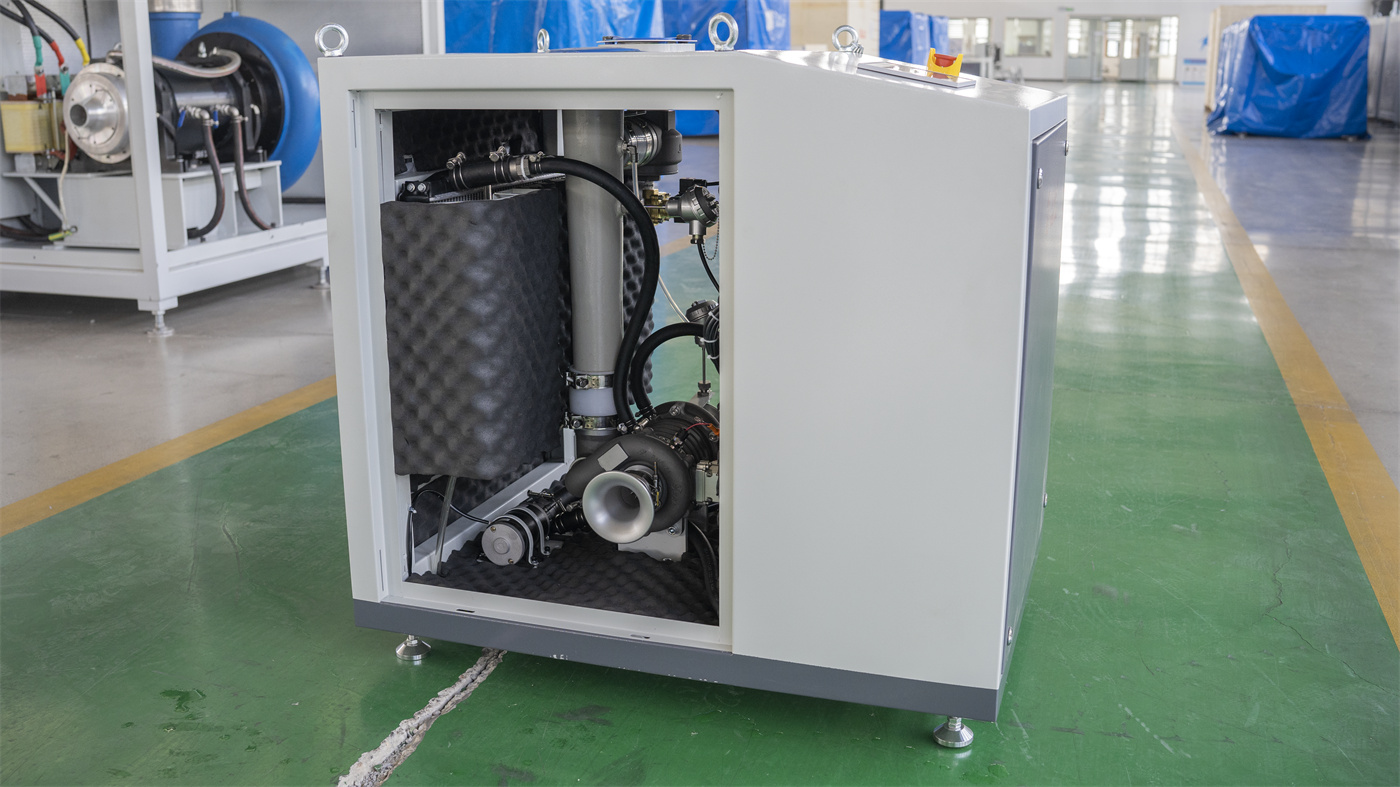

Air Foil Bearing Turbo Blower

Flow range: 5~500m³/min

Pressure rise: 20~120kPa

Based on the thermal multiphysics coupling design technology of electromagneticmachine, the R&D team independently developed a permanent magnet synchronousmotor (PMSM); Through the electromagnetic optimization design technology of high.speed permanent magnet motor coordinated with the control strategy, the problems oflarge rotor heat, high torque ripple and large motor noise are solved, so that it has theadvantages of high reliability, high temperature resistance and low wind resistance lossThe design and process of rotor structural integrity were overcome, and a permanentmagnet synchronous motor with high power density, low cost and high efficiency wasdeveloped.

Product Introduction

Air Foil Bearing Turbo Blower is a product of high efficiency, energy saving and environment-friendly. Simple mechanical structure, less moving parts, better control robustness and convenient maintenance. It adopts automotive-grade oil-free and high-reliability dynamic pressure foil bearing of no-friction running with less mechanical loss. Adopt advanced PMSM technology, the max rotary speed could achieve 95000 rpm, and it takes only 5s to run at full-speed. The motor efficiency up to 97%, achieves dual first grade standard.

Air Foil Bearing Double-suction High-speed adopts high-efficiency ternary flow impeller of wide working range, breaks through the key technology of low specific speed design and has high efficiency. The integrated special design makes its noise level ≤75 dB(A) and vibration lesss than 12um. It adopts stepless speed adjustment that the blower can be quickly start and stop, the number of continuous start and stop exceeds 200,000 times.

Product Technology

1. Foil bearing has physical contact between the rotor and the bearing before starting. The relative movement of the rotor and the bearing generates air pressure when starting. When the rotor rotates, the speed of the air around the rotor can be converted into pressure energy, and the air pressure makes the rotor float when the rotor reaches a certain rotation speed and plays a lubricating role.

2. Shandong Zhanggu independently researched and developed the fourth generation of multi-simply supported beam dynamic pressure air suspension bearing, which can reach 255,000 times of start and stop life and 20 years of durable operating life; it meets ISO16750-3 automotive-grade random vibration and 25G acceleration impact vibration standards; it effectively solves the traditional mechanical bearing transmission system problems of low efficiency, short life, and the need for regular maintenance and lubrication.

3. A high-performance aerodynamic design approach for wide working conditions:

By studying the influence of impeller and volute flow on efficiency and working stability, the R&D team proposed a flow control method and a pneumatic optimization design method to improve the performance of the main engine, which greatly improved its efficiency.

4. Ultra-high speed and high power permanent magnet synchronous motor technology:

Based on the thermal multiphysics coupling design technology of electromagnetic machine, the R&D team independently developed a permanent magnet synchronous motor (PMSM). Through the electromagnetic optimization design technology of high-speed permanent magnet motor coordinated with the control strategy, the problems of large rotor heat, high torque ripple and large motor noise are solved, so that it has the advantages of high reliability, high temperature resistance and low wind resistance loss. The design and process of rotor structural integrity were overcome, and a permanent magnet synchronous motor with high power density, low cost and high efficiency was developed.

5. Automotive grade oil-free and highly reliable Foil bearing technology:

A joint R&D team of "automotive-grade oil-free and high-efficiency foil bearings" has been set up, and foil dynamic pressure foil bearings with suitable rigidity, high damping, high vibration resistance, high reliability and low loss have been developed to meet the random vibration indicators and shock vibration standards of automotive standards.

6. High-speed rotordynamic design method

The high-speed rotordynamic design method is a key technology to ensure the stable operation of the rotor at high speed, which is closely related to the rotor structure and bearing stiffness, and is highly coupled with the motor design, aerodynamic design and bearing design.

7. Thermal management design techniques

The R&D team has applied the thermal management design and optimization technology of the secondary air system of aero-engines across borders, forming unique design technology and products.

8. Efficient drive control technology

The R&D team has developed a new high-efficiency conversion topology, thermal multiphysics integration and electromagnetic compatibility technology of high-density electromagnetic machine, which solves the problems of large switching loss, low efficiency and poor electromagnetic compatibility performance. The high-speed permanent magnet vector control, decoupling and delay compensation technology has been developed to improve the efficiency and reliability of the system, solve the problem of poor torque stability of high-speed motor, and form an advanced high-speed permanent magnet motor control solution.

Company Profile

Shandong Zhangqiu Blower Co., Ltd. was founded in 1968. With more than 50 years of experience in blower design, production, and manufacturing technology, the company has established two Sino-Japanese joint ventures and set up a branch in the United States, becoming the first domestic blower manufacturer to open branches abroad.

The company’s overall development strategy is: “Develop main business, pioneer new fields, innovate, and cooperate to become a great company.” Its working concept is: “Do the best.” Through continuous development, it has grown into a modern large-scale mechanical processing enterprise integrating the design, production, and sales of Roots blowers, centrifugal blowers, industrial pumps, ventilators, industrial water treatment projects and equipment, pneumatic conveying systems, electrical equipment, MVR evaporation concentration and crystallization technology, and complete systems.

The industrial park covers an area of 430,000 square meters, providing ample space for leapfrog development and joint venture cooperation with enterprises from around the world. The company was successfully listed on the Shenzhen Stock Exchange on July 7, 2011, with stock code: 002598. This marked a new milestone in the company’s development history.

With the in-depth advancement of national industrial policies and supply-side structural reforms, and leveraging its own advantages and market opportunities, the company is implementing a relevant diversified business strategy. It is actively developing three major industrial platforms: intelligent manufacturing, environmentally friendly water treatment, and new material development and application. By continuously increasing R&D investment and strengthening the integration of external resources, these three platforms have achieved rapid growth.