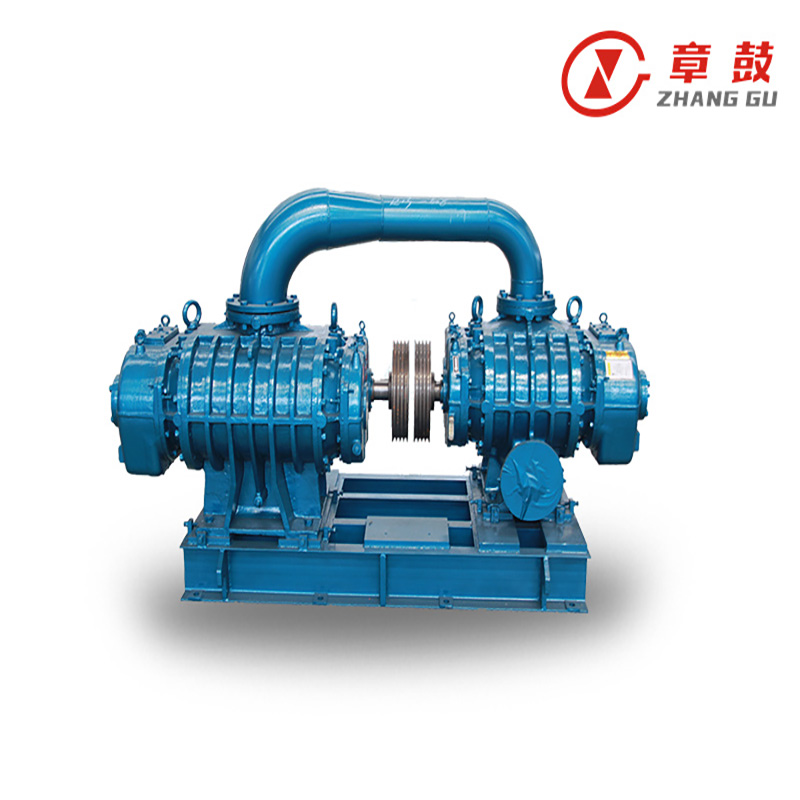

TRR Two-stage Roots Blower

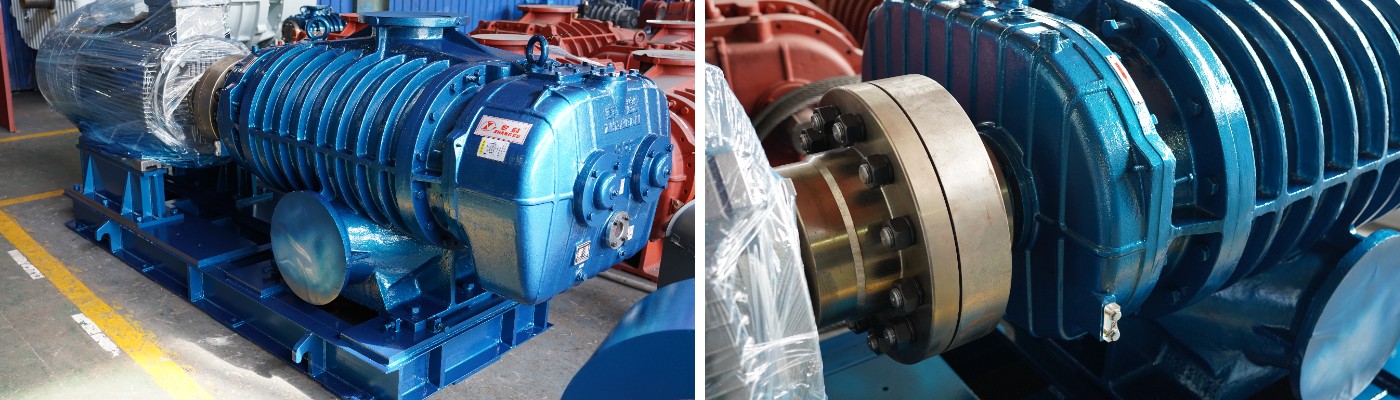

Two-stage fans, distinguished by their dual-impeller (or dual-stage) design that enables sequential airflow compression, have become a critical solution for applications requiring high static pressure or consistent airflow under varying load conditions. Unlike single-stage fans that rely on a single impeller to generate pressure, two-stage models leverage two interconnected stages to optimize performance—delivering unique benefits across industrial, commercial, and specialized sectors

The most defining advantage of two-stage fans is their ability to generate significantly higher static pressure compared to single-stage counterparts. In the first stage, the primary impeller accelerates airflow and builds initial pressure; the second stage then receives this pre-pressurized air, further compressing it to reach the required pressure levels. This sequential (pressurization) allows two-stage fans to achieve static pressures of 500–2,000 Pa or higher—a range that single-stage fans often struggle to match, especially at high airflow rates. This makes them ideal for applications where air must overcome significant resistance, such as industrial duct systems with long runs, high-density filter banks (e.g., cleanrooms, dust-collection systems), or enclosed spaces requiring forced ventilation (e.g., underground tunnels, large warehouses).

Two-stage fans excel at maintaining consistent airflow even when operating conditions change. Single-stage fans often experience airflow drops when pressure resistance increases (e.g., clogged filters, expanded duct networks), but the dual-stage design mitigates this issue. The first stage ensures a steady air supply to the second stage, which adjusts its output to compensate for fluctuations in system resistance. For example, in a manufacturing facility with variable dust levels (where filter clogging varies throughout the day), a two-stage dust-collection fan will maintain consistent suction power—preventing downtime caused by insufficient airflow. This stability is critical for processes dependent on precise air movement, such as pharmaceutical production (where airflow consistency ensures product sterility) or data center cooling (where uneven airflow risks equipment overheating).

While two-stage fans handle high-pressure tasks, they do so with better energy efficiency than oversized single-stage fans (a common workaround for high-pressure needs). Oversized single-stage fans often operate at partial load to avoid excessive pressure, leading to energy waste (due to their lower efficiency at non-rated speeds). Two-stage fans, by contrast, are engineered to operate at peak efficiency when generating high pressure—their dual stages distribute the pressure load evenly, reducing mechanical stress and energy loss. This translates to a 15–30% lower energy consumption compared to oversized single-stage fans for the same high-pressure output. For facilities with continuous high-pressure ventilation needs (e.g., chemical plants, metalworking shops), this efficiency translates to substantial annual electricity cost savings

Despite their dual-stage structure, two-stage fans are often more compact than alternative high-pressure solutions (such as multiple parallel single-stage fans or large industrial blowers). The integrated dual-impeller design eliminates the need for separate fan units or complex ductwork to combine airflow, reducing the overall system footprint by 20–40%. This is a key advantage for space-constrained environments, such as rooftop HVAC systems, small-scale industrial workshops, or indoor cleanrooms—where large equipment would disrupt operations or require costly facility modifications. Additionally, their compact size simplifies installation and transportation, as they can be maneuvered into tight spaces without disassembling critical components.