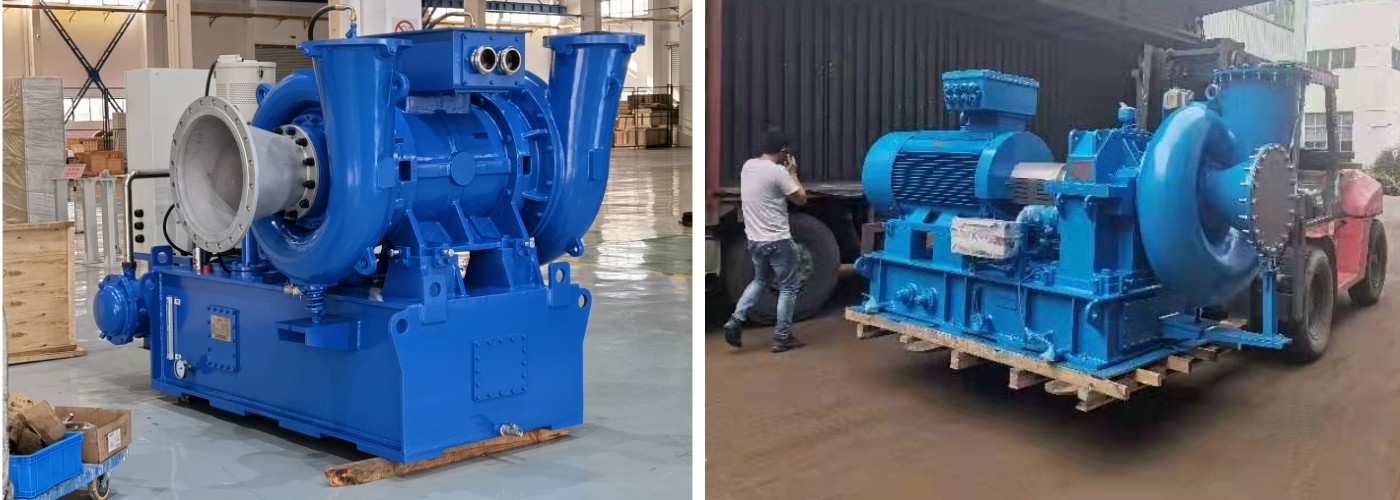

Siemens Blower

The blower is the "heart" of the pneumatic conveying system, providing the power source for conveying materials throughout the system. Its core function is to generate a stable airflow, so that powdery, granular and other bulk materials are suspended in the closed pipeline and forced to be transported.

The system mainly uses roots blowers, which are ideal for medium to low pressure and medium distance conveying needs due to their ability to provide constant flow and not be affected by pressure changes. Depending on the design and pressure, the system can be divided into suction (negative pressure) and push (positive pressure), with the blower acting as a vacuum source or pressure source.

Its application advantage lies in the realization of fully enclosed, dust-free and automated transportation, and is widely used in chemical, food, pharmaceutical, plastics and other industries for conveying raw materials, finished products and waste.

The blower is an indispensable core power source in the VPSA process, and its operational performance directly determines the productivity, oxygen purity and energy consumption level of the entire system. At the heart of the VPSA process is the separation of oxygen and nitrogen in the air through periodic changes in pressure, which is highly dependent on the pressure environment created by the blower.

During the pressurized adsorption phase of the process, a large roots blower or a high-efficiency centrifugal blower pressurizes the ambient air to 20-60 kPa and feeds it into an adsorption column equipped with zeolite zeolite zeolite. Under the action of pressure, the molecular sieve selectively adsorbs nitrogen, carbon dioxide and other components, so that oxygen can be enriched and exported as product gas through the adsorption bed. When the adsorption tower reaches saturation, the system immediately switches to the vacuum desorption stage. At this point, a specially configured Roots vacuum pump (which is still essentially a blower) starts working and pumps the pressure in the tower to a negative pressure of -40 to -60 kPa. The vacuum environment significantly reduces the partial pressure of the absorbed gas, so that the adsorbed impurity gas is quickly detached from the zeolite and discharged through the exhaust system, so as to complete the regeneration process of the adsorbent and prepare it for the next cycle.

It can be seen that the blower perfectly works together in the VPSA process to fulfill the dual mission of "pressure" and "suction": the positive pressure end provides the impetus for oxygen separation, and the vacuum end creates the necessary conditions for the regeneration of the adsorbent. The stability of its operation, the pressure and vacuum levels provided, and the overall energy consumption control together constitute the key factors affecting the economic efficiency and technical indicators of the plant, so the energy-efficient roots unit has become the preferred configuration of modern VPSA oxygen generation systems