Best Centrifugal Vacuum Pump

Blower casing and return vanes are optimally designed to match the impeller sufficiently,lower flow losses as it is streamline designed.

Combined Impeller's aerodynamic efficiency is high by applying ternary flow meridian plane and compound profile technology.

Inlet guide rings are provided for impeller to improve its fluidity.

Aerofoil style return vanes design getting higher converting efficiency of static pressure energy and lower flow losses.

Blower performance is optimized by applying fluid-analysis technology and its polytropic efficiency up to 78%.

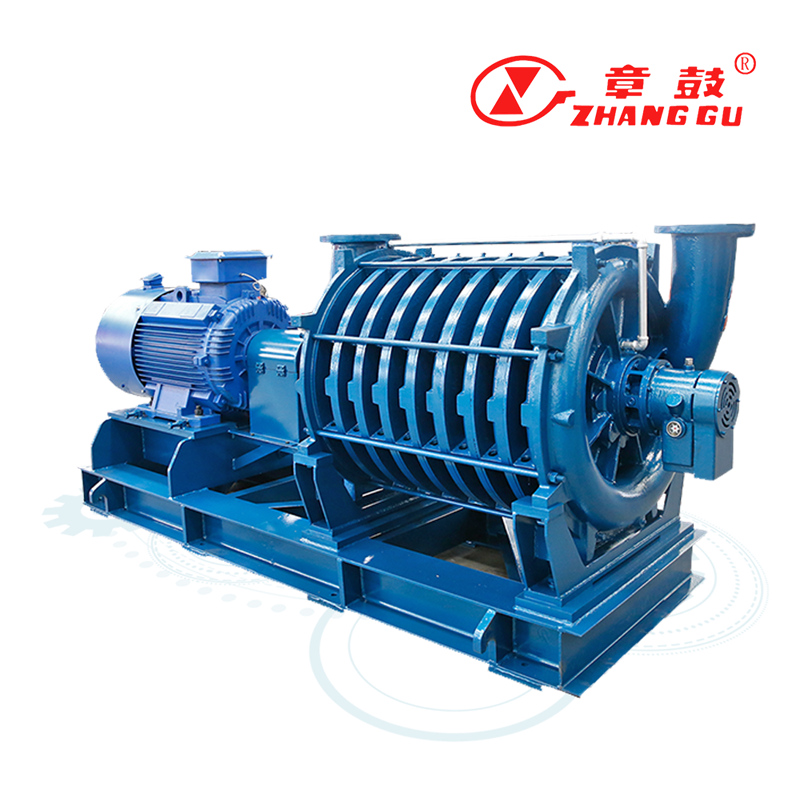

The MC Series Multi-stage Centrifugal Vacuum Pump with cast iron structure represents a globally advanced, high-efficiency product developed through the introduction of American technology. Incorporating multiple patented innovations, this series demonstrates significant advantages in low noise, low vibration, and high efficiency compared to domestic alternatives.

Key Features:

Optimally designed pump casing and return vanes ensure precise matching with the impeller, minimizing flow losses through streamlined pathways.

High-efficiency combined impeller utilizing ternary flow meridian plane and compound profile technology for superior aerodynamic performance.

Inlet guide rings are equipped to enhance fluid dynamics and operational stability.

Aerofoil-style return vanes improve static pressure conversion efficiency and reduce flow losses.

System performance is optimized with advanced fluid-analysis technology, achieving a polytropic efficiency of up to 78%.

Compatible with both 50Hz and 60Hz power systems without modification.

Wide adjustment range and stable performance across various operating conditions.

Impellers undergo strict dynamic balancing for reduced vibration, higher reliability, and low noise operation.

Advanced structural design with minimal wear parts, ensuring easy installation, operation, and maintenance.

Structure of product

The blower consists of stator, rotor, driving device, and other components. It has one suction inlet and two supports. The rotor is composed of multi-stage impellers. The motor and blower can be installed independently or mounted on the same common base according to the owner’s requirements (to be specified before order). The motor and blower are directly connected via a coupling (mini-type blowers use belt drive). When viewed from the motor tail end (shaft extension for mini-type models), the blower rotates clockwise.

◆ Stator

The stator is a vertically split type structure, consisting of the inlet chamber, intermediate casing, and discharge scroll case. These parts form the gas passages and are fastened with bolts. The inlet chamber, intermediate casing, and discharge scroll case are made from high-quality cast iron using rosin mold casting, ensuring minimal distortion after strict annealing treatment. The stator offers high precision and coaxiality, guaranteeing stable operation of the rotor assembly.

◆ Rotor

The rotor consists of impellers, main shaft, shaft sleeve, half coupling, and other components. The main shaft is made of high-quality carbon steel and undergoes quenching and tempering. After assembly, the rotor is dynamically balanced to ensure steady and reliable operation.

◆ Impeller

Depending on requirements, cast impellers or welded impellers are used. Cast impellers are precision-cast from high-strength aluminum alloy. Welded impellers are constructed from a hub, cover, and vanes. During welding, multiple heat treatments are applied to eliminate welding stress. Each impeller is dynamically balanced and undergoes high-speed testing after precision machining.

◆ Bearing Housing

The bearing housing is made of cast iron and is disposed on both sides of the blower for easy installation and replacement of bearings. It includes thermal and vibration monitoring holes. Configurations can be customized according to owner requirements. Standard blowers feature air-cooled bearing housings, with water-cooled options available upon request.

◆ Bearing and Lubrication

The bearings are SKF products with a design life of 100,000 hours, lubricated with high-quality lubricating oil.

◆ Seal

Multiple non-contact labyrinth seals are installed at the front and end of the main shaft and at each impeller stage, ensuring excellent sealing performance with minimal leakage.

◆ Oil Tank

Standard blowers use a large oil tank to reduce oil temperature without water cooling, extending the service life of lubricants and bearings. The oil tank employs a double oil-chamber splash lubrication system to provide sufficient lubrication while preventing oil foaming and leakage. An oil level indicator and vent are mounted on the oil tank.

◆ Shaft Seal

Shaft seals are located on both sides of the blower and can be replaced without disassembling the unit. Standard blowers (for air) use labyrinth seals, while special gas blowers use carbon ring seals.

◆ Drive

Mini-type blowers use belt drive, while other models are equipped with flexible pin couplings or diaphragm couplings.

Quality Guarantee

ISO9001 Quality Certification

Product Fabrication and Design Standard: JB/T7258-2006 "General-purpose Centrifugal Blower"

Test Standard: JB/T3165-1999 "Thermal Performance Test for Centrifugal and Axial Blowers and Compressors"

Strict control of each manufacturing process for parts, with comprehensive product documentation.

Control System

According to user requirements, a highly operable Local Control Panel (LCP) and a Central Control Panel (MCP) for parallel operation of multiple blowers can be provided. The MCP enables remote monitoring and local control of multiple blowers.

About us

Shandong Zhangqiu Blower Co.,Ltd (Formerly name: Shandong Zhangqiu Blower Works) is a company with over 50 years’ blower design, manufacture technology and experience. We set up two Sino-Japanese Joint-ventures and one USA branch that of 1st company in China blower industry establishing oversea branch. We are the leading enterprise in Zhangqiu local industry and main product-Roots Blower’s market occupancy is top-ranked in China blower industry.

Overall developing strategy: “Develop main business, pioneer new fields and innovate, cooperate to be a great company”. Working concept: “Do the best”. Now we are a modern company integrated the design, manufacturing and sales on products of: Roots Blower, Centrifugal Blower, Fan, Industrial Pump, Pneumatic Conveying System, Electrical Equipment, MVR Evaporation, Concentration and Crystallization system, Waste Water Treatment Product and Service and etc.

In 2005, we moved to newly built high-standard modern industrial park. This new industrial park covers an area of 430,000 m2 with complete facility and magnificent office building providing wide developing space for cooperation with oversea company and great-leap-forward development of us.

In July, 7th, 2011, the company was publish listed on Shenzhen Stock Exchange center. Stock code: 002598. This is a great development milestone of us.