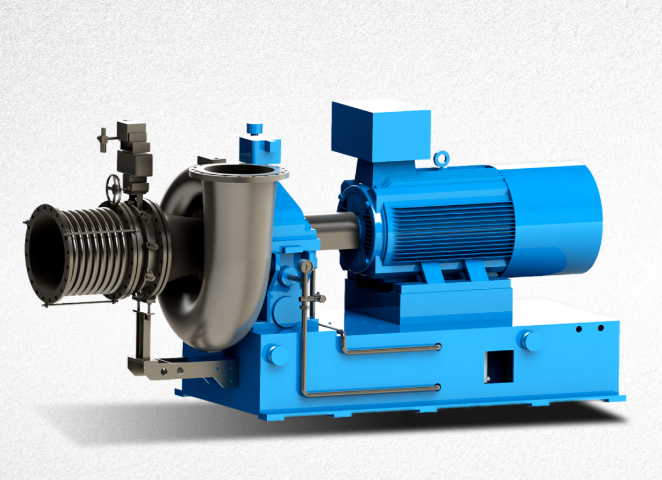

High-speed Centrifugal Blower

The single-stage high-speed centrifugal blower, guided by the energy and power technology authority of Beihang University, integrates resources in research, technology, production, and manufacturing that represent the highest standards in China's aerospace power sector. The aerodynamic performance and structural design of this series of products reach the advanced level of similar products both domestically and internationally.

Zhanggu Centrifugal Fan/Single Stage High Speed Centrifugal Blower Product Details

Product introduction: Kinetic energy empowerment, pressure victory - the core advantages of Zhanggu centrifugal fans

Zhanggu has been deeply involved in the field of fluid machinery for many years, relying on strong technology accumulation and resource integration capabilities, to create centrifugal fan series products (including single-stage high-speed centrifugal blowers), with scientific principles as the cornerstone, with cutting-edge technology as the support, to achieve efficient conversion of kinetic energy and potential energy, with excellent aerodynamic performance, optimized structural design, to become the preferred equipment for fluid transportation in the industrial field, its core performance has reached the advanced level of similar products at home and abroad, providing stable power guarantee for efficient production in various industries.

1. Core working principle: scientific transformation, efficient empowerment

Based on the core principle of "kinetic energy conversion into potential energy", the Zhanggu centrifugal fan realizes the efficient acceleration, deceleration and flow direction adjustment of gas through the precisely designed high-speed rotating impeller, and finally completes the efficient conversion of kinetic energy to potential energy (pressure) to ensure the stability of gas transportation and high pressure requirements.

1. Single-stage centrifugal fan workflow

The gas enters the impeller smoothly along the axial direction, and during the flow through the impeller, the flow direction turns radial under the action of centrifugal force, and sufficient kinetic energy is obtained. The gas then enters the diffuser, and the flow velocity is decelerated through further adjustment of the flow direction, in which the excess kinetic energy is efficiently converted into pressure energy, achieving a significant increase in gas pressure. Among them, the pressure increase mainly occurs in the impeller link, and the pressure expansion process further strengthens the pressure output to ensure that the single-stage equipment can meet the pressure requirements of most scenarios.

2. Multi-stage centrifugal fan workflow

When the gas completes the kinetic energy-potential energy conversion of the single-stage impeller, the reflow can accurately guide the airflow into the next stage impeller, and gradually increase the gas pressure through multi-stage continuous conversion and pressurization, achieve ultra-high pressure output, and adapt to the use needs of high-demand industrial scenarios.

2. Product core advantages: technology leadership, excellent quality

1. Authoritative technology leads, core performance leads

Led by the authority of energy and power technology of Beihang University, Zhanggu single-stage high-speed centrifugal blower deeply integrates top resources such as R&D, technology, production, and manufacturing in our country's aerospace power field, transforms aviation-grade power technology into the field of industrial fans, and achieves double breakthroughs in aerodynamic performance and structural design.

2. Optimized structure design, efficient and stable operation

Relying on the experience of aerospace precision manufacturing technology, Zhanggu centrifugal fans carry out precise structural design for core components such as impellers, diffusers, and reflowers, and the impellers are made of high-strength materials and optimized aerodynamic shapes, with higher rotation efficiency and stronger fatigue resistance; The flow channel design of the diffuser and reflow fits the gas flow trajectory, reducing airflow loss, improving energy conversion efficiency, reducing operating noise and vibration, ensuring the stability of long-term continuous operation of the equipment, and greatly reducing the frequency of maintenance.

3. Applicable Scenarios: Multi-Adaptability, Empowering All Industries

Zhanggu centrifugal fans, with their flexible specifications and excellent performance, can meet gas transportation needs across multiple industries and scenarios. The core application areas include:

- Wastewater Treatment Industry: Gas transportation for aeration systems, improving wastewater treatment efficiency;

- Metallurgical Industry: Ventilation, dust removal, and gas circulation transportation during smelting processes;

- Chemical Industry: Gas transportation for chemical raw materials, pressurization of reaction vessels, and exhaust gas treatment;

- Building Materials Industry: Ventilation and drying gas transportation in cement and ceramic production processes;

- Power Industry: Boiler ventilation, and gas transportation in flue gas desulfurization and denitrification systems;

- General Industry: Factory ventilation, material transportation, air purification, and other scenarios.

4. Brand Assurance: Zhanggu Strength, Worthy of Trust

As a well-known brand in the field of fluid machinery, Zhanggu has decades of experience in research, development, and manufacturing. Always placing technological innovation at the core of its competitiveness, the brand leverages deep cooperation with authoritative research institutions to continually promote product iteration and upgrades. At the same time, it is equipped with professional R&D, production, and after-sales service teams, providing users with a full range of services from product selection, installation, and commissioning to subsequent maintenance, ensuring stable equipment operation and supporting efficient production.