C Series -Cast Iron Blower

- The shell of inlet and outlet,and retum channel of blower are fully adapt to impeller,The streamline design reduces loss.

The impeller is designed by three dimensional meidian plane and compound curve technology,enjoys higheficiency.

The impeller intake seal-inducer improves inlet fluidity of impeller.

The airfoil return-flow blade can reduces loss ,gets high static pressure.

The blower performance was optimized with fluid analysis technology,The polytropic efficiency is up to 78%.

Some blowers use Three-dimensional impeller,which have high efficiency and good performance.

After strict dynamic balance,the rotor has low vibration,high reliability and low overallnoise.

The structure of blower is advanced and reasonable Easy-wom parts are few.Installation,operation and maintenance are convenient.

Product Introduction:

Series C casting multistage centrifugal blower,based on technology of welding multistage low speed centrifugal,designed and developed by Shandong Zhangqiu Blower CO.,is new generation high efficiency product,gathering some patented technologies and longtime blower experiences of design and fabrication,which can satisfy users'appeal.

Product Features:

◆ The shell of inlet and outlet,and retum channel of blower are fully adapt to impeller,The streamline design reduces loss.

◆ The impeller is designed by three dimensional meidian plane and compound curve technology,enjoys higheficiency.

◆ The impeller intake seal-inducer improves inlet fluidity of impeller.

◆ The airfoil return-flow blade can reduces loss ,gets high static pressure.

◆ The blower performance was optimized with fluid analysis technology,The polytropic efficiency is up to 78%.

◆ Some blowers use Three-dimensional impeller,which have high efficiency and good performance.

◆ After strict dynamic balance,the rotor has low vibration,high reliability and low overallnoise.

◆The structure of blower is advanced and reasonable Easy-wom parts are few.Installation,operation and maintenance are convenient.

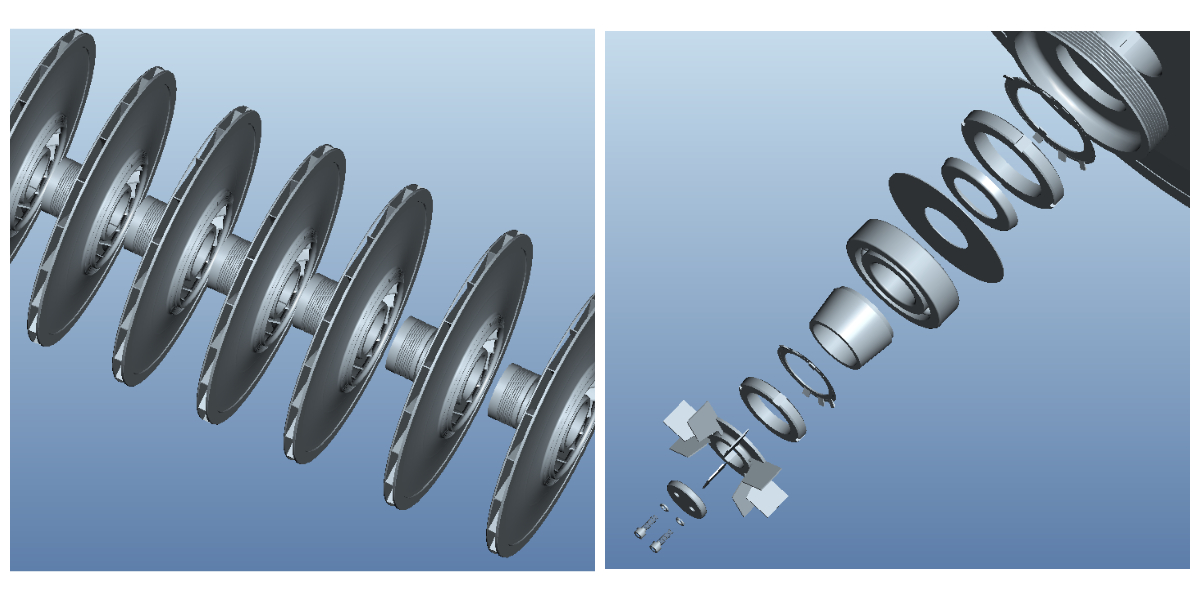

Structural of Product:

The blower is consists of stator,rotor,driving device and so on.It has one suction and two supports.The rotor consists of multi-stage impellers.Motor and blower are installed independently,or are installed on the same common base according to owner's demand(indicating before order).Motor and blower are direct connected withcoupling (The mini-type blower connect with belt).Watching from the tail of motors(For the mini-type blower,it is shaft protraction),the blowers is clockwise rotation.

◆ Stator

The stator is vertica split type structure,which is consists of the inlet chamber intermediate casing and discharge scroll case,these parts make up of the gas channels with bolts.The inlet chamber,intermediate casing and discharge scroll case are founded using high quality castiron and rosin model,having small distortion after strict anneal dispose.Stator with high precision and high coaxial can insure stable operation of rotor assembly.

◆ Rotor

Rotor is consists of impellers,main shaft,shaft sleeve,half coupling and so on.The main shaft makes use of the high quality carbon-steel,and carries through quenching and tempering.After assembly,the rotor was dynamically balanced to ensure steady and reliable running.

◆ Impeller

Based on the requirement,casting-impeller and welding-impeller are adopted.Casting-impeller is precisely cast with high strength aluminum-alloy.And the welding-impeller is welded of a hub,cover and wanes ,in the course of welding,heat treatment should be done several times to eliminate welding stress.Each single impeller is dynamically balanced and tested with high speed after precisely machining.

◆ Bearing housing

Bearing housing material is castiron,they are disposed on two sides of blower Installing and replacing bearings are easy.

There are thermal hole and vibration hole on the bearing housing.We can do diferent configuration according to different owners. Standard blower bearing housing is air-cooled.If owner need,we also provide water-cooling bearing housing.

◆ Bearing and lubricating

The bearings are SKF products,which design life are 100000 hours,and lubricated by employing high grade grease or lubricating oil.

◆ Seal

Many groups of non-contact labyrinth seals are installed on the end and front of the main shaft and every stage impeller.

They have so good sealing performance that blowers only have little leak.

◆ Oil tank

Standard blower use large-scale oil tank to reduce oil temperature without water,prolonging the life of lubrication and bearings.The oil tank adopts double oilchamber splash lubrication to provide enough lubrication and avoid the oil froth effect and oil leakage.The oil level indicator and exhaust body are fixed on the oil tank.

◆ Shaft seal

The shaft seals locate at two sides of the blower,which can be replaced without disassembly of body.The shaft seals include the labyrinth seal and carbon ring seal.The labyrinth seal is used at the standard blowers(air blowers).The carbon ring seal is used at the special blower(special gas blower).

◆ Drive

The mini-type blowers adopt belt drive,the other blowers adopt the flexible pin coupling or the diaphragm coupling.

◆ Control System

Electric company can provide good-operation LCP and MCP,Via MCP,many parallel blower can achieve remote monitored

and local control.

Packaging and Shipping

About us

Shandong Zhangqiu Blower Co., Ltd. has nearly fifty years of experience in fan design, production, and manufacturing technology. It has now developed into a modern large-scale machinery enterprise integrating the design, production, and sales of Roots blowers, vacuum pumps, centrifugal fans, industrial pumps, industrial water treatment engineering and equipment, heavy machinery equipment, pneumatic conveying systems, electrical equipment, and MVR evaporation, concentration, and crystallization technologies and complete systems. The company was successfully listed on the Shenzhen Stock Exchange on July 7, 2011, with the stock code: 002598.

It is a Level II enterprise for standardized work safety and has passed ISO9001 Quality Management System Certification, ISO14001 Environmental Management System Certification, Occupational Health Management System Certification, and National Military Standard Certification. Relevant products have also obtained Mining Product Safety Mark Certification, CE Certification, Energy-Saving Product Certification, and Production License.

The company has successfully undertaken multiple national, provincial, and municipal technological innovation projects. Many of its products have been included in the National "Spark" Program, Provincial Key Projects, and National New Product Program.