High Speed Vacuum Pump

CVP series high speed Turbo vacuum pump

High Efficiency & Advanced Impeller Customized Design

Excellent Energy-Saving Performance

Wide Adjustment Range & Stable Vacuum Performance

Compact Design & Reduced Footprint

Low Noise Operation

High Level of Intelligence

CVP series high speed Turbo vacuum pump is a newly developed product of high efficiency and power-saving, based on the years' experience of Shandong Zhangqiu Blower Co., Ltd. and the introduction of Beijing University of Aeronautics and Astronautics (Beihang University) professional doctor team.

The pneumatic performance and structural design of this series product has reached the leading level in China and abroad. Customized design according to the field conditions, it can be widely used in paper-making, foundry, alumina flat plate/vertical plate vacuum dewatering and other vacuum processes. Also suitable for power-saving upgrading projects to replace water ring vacuum pumps.

Product Code

CVP means Turbo Vacuum Pump.

The 1st number indicates the rated suction flow capacity (unit: m³/min).

The 2nd number indicates the rated vacuum degree (unit: kPa).

Multiple combinations of vacuum degree and flow capacity can be listed.

As per this example, use "" to separate different specifications.

“D” means direct drive; if null, it means driven by gearbox.

“2” means two-stage blowers in series; if null, it means single-stage.

Product Features

High Efficiency & Advanced Impeller Customized Design | Excellent Energy-Saving Performance

The impeller is designed using three-dimensional flow theory and fully simulated with 3D computational fluid dynamics. Performance of the turbo vacuum pump is predicted through advanced flow analysis technology, achieving adiabatic efficiency up to approximately 85%. Its efficiency is 20% to 45% higher than other vacuum pumps under the same vacuum and flow conditions.

Each impeller is custom-designed according to the user’s operating parameters to ensure operation within the high-efficiency zone, delivering significant energy savings.

Wide Adjustment Range & Stable Vacuum Performance

The turbo vacuum pump offers a broad flow capacity range, adjustable via VFD (Variable Frequency Drive) and OGV (Inlet Guide Vane) technologies, ensuring stable vacuum levels even under large flow fluctuations. An anti-surge device is included to effectively prevent surge issues.

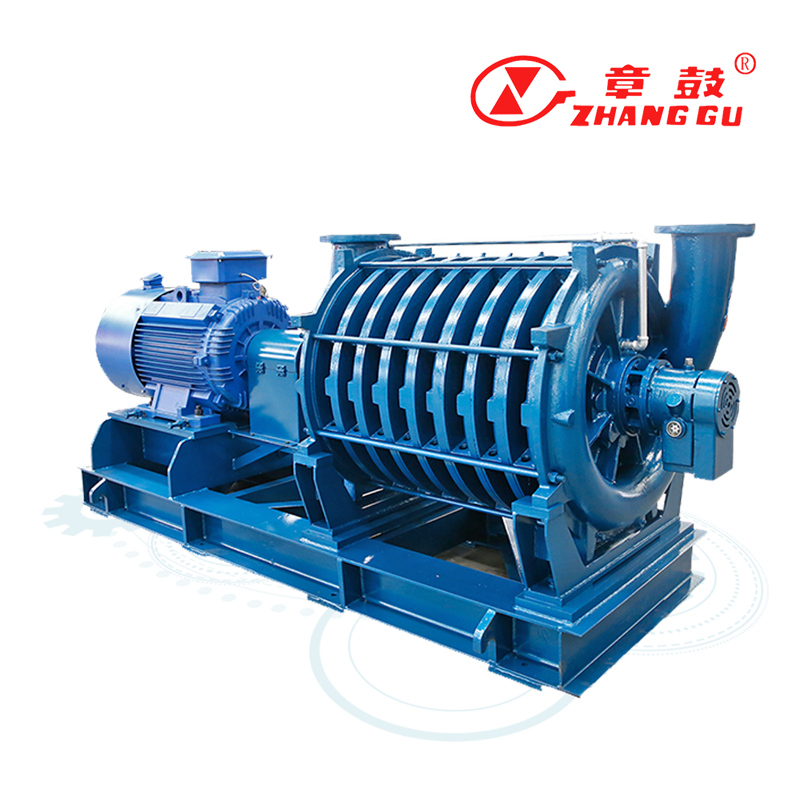

Compact Design | Reduced Footprint

The unit adopts an integrated skid-mounted structure. The pump body is directly connected to the gearbox, and the lubrication system, gearbox, and motor are mounted on a common base that also functions as the oil tank. A single unit can be configured with dual air ends to meet diverse vacuum requirements. The system is lightweight, compact, and space-saving.

Low Noise Operation

Advanced spiral case and impeller design suppress both discrete and broadband noise, enabling active control of aerodynamic noise and promoting faster sound decay.

Minimal Wear Parts | Easy Installation & Maintenance

With fewer wear parts, the pump requires less on-site maintenance and allows quick, straightforward installation.

High Level of Intelligence

A comprehensive PLC-based monitoring system covers bearing vibration, temperature, inlet/outlet pressure and temperature, anti-surge control, start-stop interlock protection, fault alarms, lubricating oil pressure, and temperature. All data is transmitted in real-time to the "Zhanggu Cloud" intelligent platform, enabling users and engineers to monitor equipment status remotely and in real time.

Main structure

Regulating Mechanism

An OGV (Inlet Guide Vane) device can be selected according to specific working conditions. The OGV assembly consists of a diffuser disc, guide vanes, transmission mechanism, actuator, and other components. It ensures a constant vacuum degree even under fluctuating flow conditions, thereby guaranteeing system stability and reliable performance.

Inlet Separator

To handle impurities such as pulp, sand, grout, and other particulates in the vacuum pump suction medium, our company has developed a specialized inlet separator. This device effectively removes solid contaminants from the gas stream, ensuring only clean air enters the vacuum pump. By preventing impeller wear and scaling, the separator helps maintain high impeller efficiency and extends the service life of the equipment.

High-Speed Permanent Magnet Synchronous Motor

A permanent magnet synchronous motor is adopted as the standard drive. It offers higher efficiency and complies with the Class 1 energy efficiency grade as specified in the GB30253-2013 standard. With a rated operational efficiency ranging from 94.5% to 97%, it achieves 4–6% higher efficiency compared to asynchronous motors.

The motor features a simple structure, compact size, and lower noise levels. It also delivers enhanced energy savings during no-load operation.