Geared Turbo Blower

Wide Adjustment Range, Stable Vacuum Degree

Compact Design, Less Footprint

Low Noise Level

Fewer Wearing Parts, Convenient Installation and Maintenance

High Degree of Intelligence

PRODUCT INTRODUCTION:

CB series High speed Turbo Blow er is developed by Jiangsu zhang gu LIP ORI power Technology co., Ltd adopting advanced aero turbo machinery technology, based on the years 'accumulated experience of shandong zhang qi uB lower Co., Ltd.

This series products achieve advanced technology level both in china and abroad on pneumatic performance and structure design, are widely used in wastewater Treatment, power plant, petroleum, chemical, Non-ferrous Metallurgy, Gas treatment, solid waste Treatment.

PRODUCT FEATURES:

Advanced impeller profile curve and high efficiency

The ternary flow theory design of the impeller and the application off low analysis technology forecasting performance of blower make the Adiabatic efficiency to reach up82%.

The flow capacity can be centrolled in the wide rangeand the blower can be applied to variety of working conditions

3options on blower flow capacity adjustment: VFD, IG V(Inlet Guide vane), OGV (outlet Guide vane) , wide adjusting range and keep high efficiency under non-rated working condition. The provided anti-surge device can prevent the surge problem effectively.

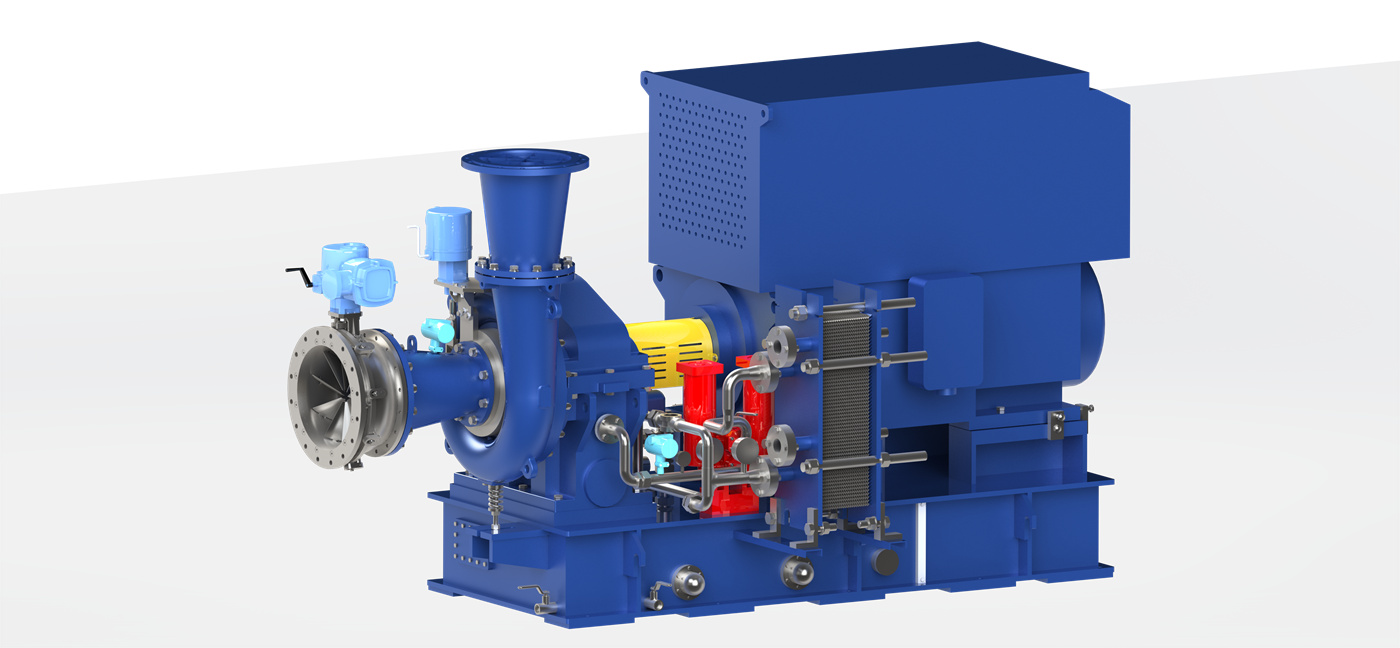

The compact blower structure and small size

The blowers are adopted integrated structure of assembly- type, in details, the blower body is assembled on the casing of gear accelerating box, the lubricating oil system distributed , the motor and gear accelerating box are installed on the common pedestal compactly;the pedestal doubles asa oil tank.

After strict dynamic balance, the rotor has low vibration, high reliability and low overall noise.

The Moment of inertia of rotor is small, the startup and stop time has been decreased and the oil box with high oil level and accumulator has been abrogated. compare to other style blowers with same flow capacity and pressure rise, this product enjoy s low energy consumption, lightweight and small size.

The structure of blower is advanced and reasonable. Easy-worn parts are few. Installation, operation and maintenance are convenient.

The parameters(such as bearing vibration of whole machine, temperature rise; inlet and outlet pressure and temperature; anti-surge control;start of the interlock protection; failure alarm; oil pressure of lubricating system, oil temperature control and so on) are controlled by programmable logic controller that can be get real-time control. Less wearing parts and the daily maintenance is convenient.

High degree of intelligence

The bearing' s vibration, temperature, the inlet and outlet pressure, temperature, anti-surge control, start-stop interlock protection, fault alarm, lubricating oil pressure, oil temperature and a series of monitoring and control system are controlled by pLC, and real-time transmission to the "zhang gu cloud" intelligent cloud platform, users can real-time monitoring equipment running status with project engineer.

volute casing

This part adopts round section vo lute casing, and the profile line of the scrollwall is designed tobe the logarithm spiral line, meet the air flow law of motion and itis low impact to blower, so the blow er is high flow efficiency, low vibration and lownoise.

Gear

The acceleration gear pair adopts the invo lute tooth profile. The surface ofgearwheel and pinion gets through the grinding and nitride-harden treatment tomaintain the high speed stable operation, low vibration and low noise. The lifetimecan be20years.

Bearing

The high-speed shaft support, composed by many flexible pads, adopts tiltingpad journal bearing. The pads could def lex around the fulcrum, its anti-vibrationperformance and automatically adiusting ability according to the variation of loadand speed are both excellent.

seal

Diverse seals are available for different transported gas: Labyrinth seal, carbonRing seal + lnert Gas purging and etc. Integrated design or split design for differentconditions.

LUBRICATION SYSTEM:

The lubrication system is consists of the oil tank and the bil pipeline.The pedestal doubles as a oil tank, the immersiontype electric heater and temperature control switch are both included in the oil tank, Lubrication piping is composed by:master oil pump, auxiliary oil pump, binocular filter and heat exchanger. The main oil pump would be driven by the low.speed gear and it supplies the pre-lubrication to gear and bearing with certain pressure when the units operate normally.The electric pump would supply the pre-lubrication before the units start and keep the oil pressure still under theemergency and downtime. The electric pump also plays a role of stand-by oil pump. The oil filter with double cylinder ishigh-precision. The pressure difference alarm device on filter is also equipped.

MONITORING AND CONTROL SYSTEM:

The monitoring and control system are designed for protecting running of high-speed centrifugal blower. The startupis provided with the mode of interlock,antisurge control,the accessorial pump automatic start & stop according to theoil pressure, protection for over high bearing temperature and vibration. There are oil pressure sensors on oil-supplyingpipeline,oil temperature sensors following oil coolers, temperature sensors and vibration sensors on high speed slidingbearings.The inlet and outlet pipeline are equipped with primary & secondary meters and transmitter to measure airtemperature & pressure,so that,it can monitor the parameters real-time , to ensure the safe,stable and reliable operation of the blower.