Characteristics and application of centrifugal fan for rock wool factory

Centrifugal fans are the "lungs" and "veins" of rock wool production lines, and their performance directly affects product quality, production efficiency, and operating costs. Its characteristics and application analysis are as follows:

1. Excellent high temperature and corrosion resistance

Analysis: The production of rock wool involves high-temperature melting of raw materials (temperature exceeding 1000 ℃) and curing of phenolic resin (about 200 ℃), and produces corrosive acidic gases. Therefore, centrifugal fans used near furnaces, cotton collectors, and curing furnaces must be made of high-temperature resistant alloy steel (such as 310S stainless steel) or undergo special anti-corrosion coating treatment. This ensures the long-term stable operation of the fan under harsh working conditions, preventing production interruptions caused by high-temperature deformation or corrosion failure, and extending the equipment life.

2. Accurate frequency conversion and air volume control

Analysis: The fiber diameter, distribution uniformity, and solidification degree of rock wool are extremely sensitive to the stability of air flow. For example, in the cotton collection process, even small fluctuations in wind speed can affect the uniformity of the cotton felt. Modern rock cotton threads commonly use variable frequency speed regulating fans, which are controlled in real-time by PLC or DCS systems based on feedback from process sensors such as pressure and temperature. This achieves precise and smooth adjustment of air volume, ensuring consistency in product quality, and is also the key to achieving energy-saving operation (avoiding valve throttling losses).

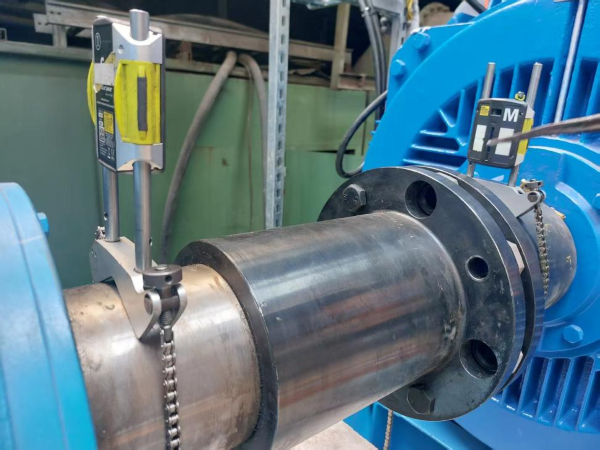

3. Extremely high operational reliability and stability

Analysis: Rock wool production lines usually operate continuously for 24 hours, and an unplanned shutdown can cause significant economic losses. This requires centrifugal fans to have extremely high reliability. Its features include: heavy-duty bearing design (ensuring long service life), robust rotor dynamic balancing (reducing vibration and running smoothly), and simple maintenance structure (facilitating quick maintenance). High reliability is the cornerstone for ensuring the continuous, stable, and efficient operation of production lines.

4. Ability to operate with high air volume and high negative pressure

Analysis: Different process stages have different emphasis on the performance requirements of fans. The fiber forming and cotton collection processes require fans to provide a huge amount of air to complete the stretching, cooling, and transportation of fibers; The dehumidification fan of the curing furnace needs to create a high system negative pressure in order to efficiently discharge a large amount of moisture and volatile substances from the furnace. Fans must be designed and selected according to their installation location to meet specific process aerodynamic requirements.

5. Efficient energy-saving and environmentally friendly design

Analysis: Ventilators are a major power consumer in rock wool factories, and their energy-saving performance directly affects production costs. The current mainstream design saves energy through various means: using efficient ternary flow impellers (to improve aerodynamic efficiency), paired with high-efficiency motors (such as IE4 and IE5 energy efficiency levels), and the aforementioned variable frequency speed regulation technology. In addition, its reliable sealing performance (preventing oil leakage) and collaborative work with the dust removal system also constitute an important part of the factory's environmental compliance.

6. Integration and Intelligence Trends

Analysis: With the development of Industry 4.0, the new generation of rock wool factory centrifugal fans are no longer independent components, but highly integrated intelligent systems. The fan itself is equipped with vibration and temperature sensors to monitor the operating status in real time, achieve predictive maintenance, and avoid sudden failures. The data is uploaded to the central control system, and operators can remotely monitor the energy consumption and efficiency of all wind turbines, optimize scheduling, and comprehensively improve the intelligent management level of production.

The centrifugal fan used in rock wool factories has evolved from a simple functional equipment to a complex system that needs to meet comprehensive requirements such as high temperature resistance, corrosion resistance, precise control, high reliability, high efficiency and energy saving, and intelligence. Correctly selecting, applying, and maintaining centrifugal fans is one of the core technologies for building an efficient, high-quality, and low-carbon rock wool production line.