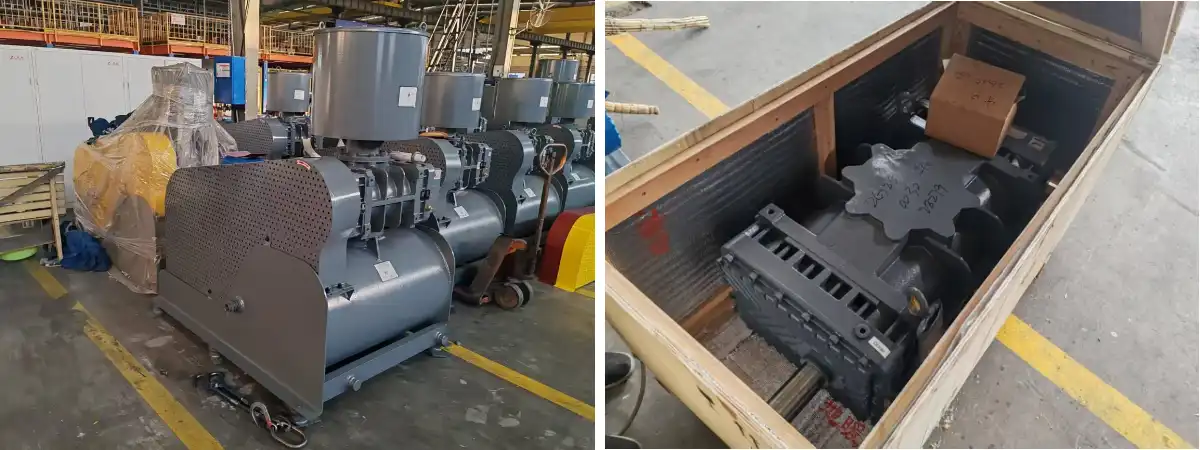

Application of Roots Blower in the Food Industry

1. Core function: Provide oxygen required for biochemical reactions

In aerobic fermentation processes such as the production of soy sauce, vinegar, amino acids, yeast, antibiotics, beer, etc., microbial strains require a large amount of oxygen for growth, metabolism, and synthesis of target products. The Roots blower continuously presses sterile, oil-free compressed air into the bottom of the fermentation tank through the aeration system (pipeline, aeration head/disc), providing dissolved oxygen (DO) necessary for microbial life activities.

2. The key to ensuring fermentation quality and efficiency: stable air flow

Roots blower is a positive displacement fan, and its biggest feature is that its output air volume does not fluctuate significantly with changes in the liquid level or back pressure of the fermentation tank at a constant speed. This means that regardless of the stage of fermentation, it can provide a constant and reliable oxygen supply for microorganisms. A stable dissolved oxygen environment is the cornerstone for ensuring consistent microbial metabolic pathways, improving product yield, and inter batch stability.

3. Absolutely oil-free, eliminating pollution risks

The fermentation process should avoid contamination the most. The lubrication system of the Roots blower is completely isolated from the compressed air chamber, and efficient shaft sealing technology (such as labyrinth seals and mechanical seals) is used to ensure that the output air is absolutely free of oil. This completely avoids the toxicity and inhibition of microbial strains by oil molecules, as well as contamination of the final food or pharmaceutical products, fully complying with strict hygiene standards such as GMP and FDA.

4. Dealing with harsh working conditions of high temperature and humidity

The fermentation tank is in a high temperature and high humidity environment. The sturdy structure and insensitivity to the medium of the Roots blower enable it to withstand such humid conditions with a certain amount of water vapor. Even with a small amount of water vapor backflow, it is not prone to failure like other precision compressors, demonstrating extremely high reliability and robustness.

5. Accurate dissolved oxygen control and energy-saving operation

Modern fermentation processes control the Roots blower through a frequency converter (VFD). Operators can adjust the fan speed in real-time according to the precise requirements of dissolved oxygen at different stages of fermentation, thereby accurately controlling the air supply volume. Reducing the speed during the low oxygen consumption stage can bring significant energy-saving effects (power consumption is approximately proportional to the cube of the speed), significantly reducing operating costs.

6. Easy to maintain and long lifespan

Fermentation production is usually carried out in continuous batches, requiring extremely low equipment failure rates. The structure of Roots blower is simple, and the main daily maintenance is to regularly replace the lubricating oil and air filter. The maintenance cost is low and convenient. Its sturdy cast body design ensures that it can withstand 24-hour uninterrupted long cycle operation.

In the fermentation process, the Roots blower is not a simple blowing device, but a key process core directly related to the activity of bacterial strains, metabolic efficiency, product quality, production costs, and energy consumption. Its four core advantages of stable air flow, oil-free cleanliness, durability, and easy control make it the preferred equipment for aeration systems in the global fermentation industry.